A Quicker Guide to Understanding 4 Layer PCBs

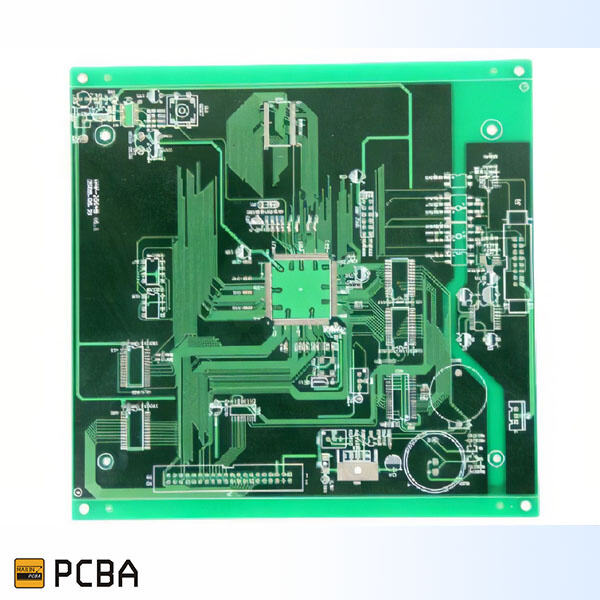

Printed circuit board or PCB is a very important thing in electronic devices and 4 layer pcb is a kind of pcb. The following are the layers of a four-layer Pcb: insulation, conductive layer, insulation again more complex circuit designs can be made with this configuration. Although mailin a circuit board may sound technical, 4 Layer Pcb is actually quite simple.

What's the point of having four layers in the electronics? These things are small but they are the most important components that enable packaging more elements into a tight space. To pack more in smaller space electronic manufactures add up layers to mailin circuit board making thinner and sleeker electronics devices.

Benefits of Designing with Four Layers A good design is not just about improving performance while meeting trim targets; mailin electrical circuits involves optimizing space utilization at once so as to cut down on signal path length and enhance device performance. However, manufacturing these boards can take longer than usual which will lead to higher prices since production costs would have increased too.

Four layer PCB design tips/tricks cannot be ignored because they bring out the best potentiality of any given four layered board design. First off all materials must be top notch quality both for conductive parts as well insulating ones as well. Secondly electronic components should also have an optimized placement of components on board with required trace spacing carefully planned during circuit layout design stage Conduct testing well prior to the design process (if possible) in order cut down both your risk and expensive overruns a mistake is discovered.

Applications- Complex Electronic Systems in 4 Layer PCBs

Different situations call for different types of printed circuit boards; one such example being when dealing with complex electronic systems where multi layered pcbs are necessary. For example in a smartphone there are many components which need to be mounted on small area hence use of these boards is inevitable. On the other hand medical devices usually have lots of complicated circuitry thus require use of four layer pcbs.

Just as we expect technological advancements within our gadgets so should there also be changes made in manufacturing methods used when producing them since this two work together. The trend currently is towards smaller and sleeker electronic devices which has led to reduction in size or thickness of pcb through costly cuts. Moreover, flexible materials enable production different shapes/form factors for ic integrated circuit while better fabrication process organization through improved tech allow faster turn-around times during pcb making.

We get to know about 4 Layer Gloss Modification Low Dk Floor Tile Range Pdf Conclusion after that routing is completed. Most electronic devices require four-layer PCBs. This quality of being able to accommodate many components in a limited space contributes significantly and serves as the foundation for creating small-sized yet highly efficient electronic gadgets. There are challenges such as higher production costs; however, these are also reasons why steps towards ensuring that 4 layer PCB is built and utilized for complex electronics should work best. The current advancement in manufacturing methods shows more applications of 4 layer PCB within modern-day electronics soon coming into play

We are well aware of the unique needs of each 4 layer pcb, thus, in the single-stop delivery services offered by PCBA we place a lot of importance to the core value of "customized customer service". We provide exclusive one-on-one professional consulting services that ensure each customer receives individualized solutions. Our expert team can provide many different solutions, from the initial exploratory phase to confirmation of the specifications. They work together with the customer, adapt service processes flexibly and to meet a variety of needs of the project, whether simple or complex, with innovation and technical power.

We're specialized in delivering a solid dedication our customers to 4 layer pcb and service for their PCBA one-stop service for delivery requirements. The SMT mounting is highly precise and strict quality packaging, to the process ability of plunge plugin processing, as well as PCBA testing being a vital step to make sure high-quality production and distribution, FCT testing equipment is made plus tested relative to your client designed testing points, programs, and steps. The rings are created to meet international quality. This means that the things delivered are of outstanding reliability plus long-term performance.

are a PCBA Rapid-delivery solutions provider which sets standards for 4 layer pcb and effectiveness. normal orders have improved the production process optimized supply chain management to reduce the time for delivery of batches to just 10 days. This is far ahead of industry norms. Additionally, in wake pressing demands, we've pioneered express services for small batch orders with a remarkable turnaround of only 72 hours, making sure your projects get off to a flying start and take advantage of opportunities in the market.

In 2009, company was founded. Hangzhou Hezhan Technology Co., Ltd. boasts area over 6,000 square meters, which is outfitted with the latest cleanrooms designed specifically to electronics manufacturing. The company specializes in electronic surface mounting relies on its vast industry experience offer clients one-stop PCBA.The company employs approximately 150 staff members, 4 layer pcb production team about 100, a sales, R D and management team about 50 individuals, and an OEM division that is specialized. a revenue per year close to 50 million Yuan, Hezhan Technology has experienced substantial growth in recent years, maintaining same rate growth that more than 50% for the last three years, an indication of robust expansion phase.