Printed circuit boards (PCBs) are found in virtually every product we use nowadays, and PCBs have been an integral part of the production process. They are connectors used to connect various sections of these devices which help the systems function correctly and properly. Designing A 4 Layer PCB - The design with four layers of circuits allows the engineers to develop more complex designs and add a higher number of electronic components.

This is better illustrated if you think of a 4 layer PCB as containing four layers like that of the layered sandwich. The very highest layer — the bread, if you will — presents itself first; then a slice of cheese; and then stands tall that slab or two of ham before we see another layer to hold up whatever comes down from above. There is enjoyment in eating a sandwich, as each component adds; to the overall flavor and texture, which means that it more enjoyable than one without such individual items.

Well, you have understood the construction of multilayer PCBs or 4 layer PCB but why they are used in so many electronic devices. In general, these multi layer boards tend to be significantly more effective than single-layer PCBs. One layer is limited when it comes to the amount of components a PCB can hold, making them not efficient for more complex gadgets.

This is true for multilayer PCBs as well. They are better in efficiency and performance since they can hold more stars and connections So you will see multilayer PCBs in various devices, from smartphones and laptops to even cars, where efficiency and performance is critical.

It may seem impossible today, but we have come a long way since then and technology never fails to surprise us; 4 layer pcb design is one of the best example it offers. The development of 4 layer PCB designs allows us to develop electronic equipment that is more advanced and capable than what would have been possible if we had not used the foundation upon which it was built.

The last but not the least being that 4 layer PCBs are also budget-friendly. They can be built relatively inexpensively, and do the job you had in mindereumgetConfig.setId(url); This makes them an excellent choice for companies that need to produce high-quality electronics without paying a fortune.

Consider cramming all of the minuscule parts from a smartphone onto one layer PCB. Even nearly impossible! Although, smartphones can also be plug into lots of parts including the processor, memory,Cameras and different sensors because it is enable by 4 layer PCB Designs. Such abilities give us some amazing smart features, like Face Unlock, High-End Camera Performance and Advanced Machine Learning Applications.

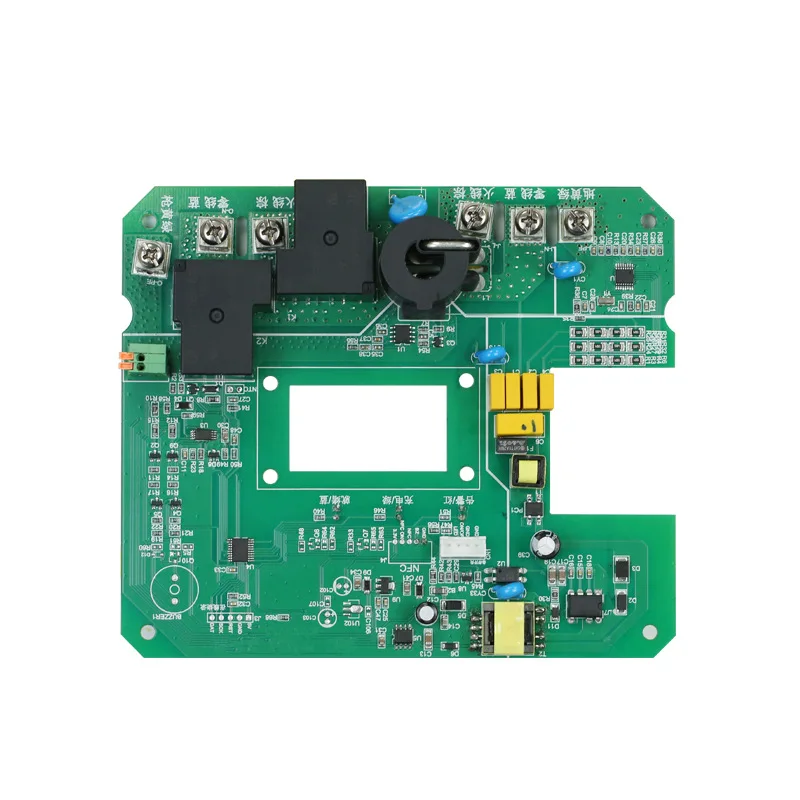

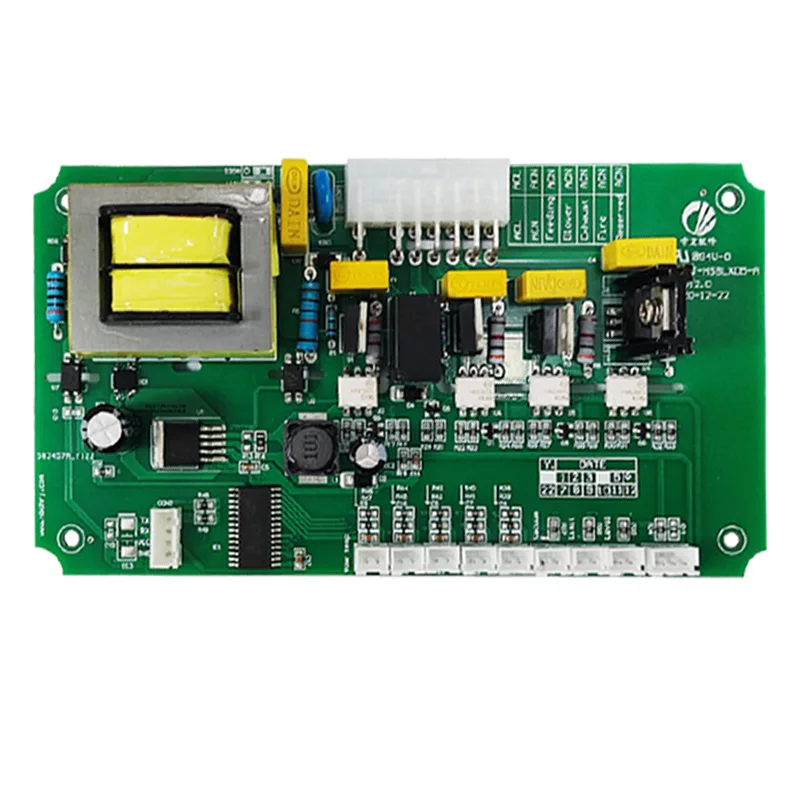

Established in 2009, Hangzhou Hezhan Technology Co., Ltd. boasts manufacturing facility 6000 square meters is equipped with state-of-the-art cleanrooms tailored for electronics manufacturing. Focusing on research and production electronic surface mounting, company based on vast industry experience provide customers with an all-in-one PCBA solution, and is also moving into small-batch manufacturing and online delivery models.There are around 150 employees employed by company. They 4 layer pcb design production team around 100 members, an R D department of around 50, sales personnel along with a management staff, and an OEM department that specialized. Hezhan Technology, with an annual turnover close to 50 million Yuan has experienced significant growth in the last few years. The company's compound annual growth rate the last three years is more than 50%, suggesting that it in a rapid expansion phase.

We are well aware of the unique needs of each 4 layer pcb design, thus, in the single-stop delivery services offered by PCBA we place a lot of importance to the core value of "customized customer service". We provide exclusive one-on-one professional consulting services that ensure each customer receives individualized solutions. Our expert team can provide many different solutions, from the initial exploratory phase to confirmation of the specifications. They work together with the customer, adapt service processes flexibly and to meet a variety of needs of the project, whether simple or complex, with innovation and technical power.

We are going to offer you a 4 layer pcb design service and a commitment to excellence in most your PCBA requirements. With high-precision SMT mounting technology strict quality packaging to your procedure capabilities of DIP plugin processing, and lastly PCBA testing as a crucial measure to guarantee manufacturing and delivery quality, FCT evaluation fixtures were created and tested to fulfill customer developed testing points, programs and steps. Every ring was created to worldwide quality, which ensures that these products delivered have powerful and long-term endurance.

are a specialist in offering one-stop PCBA speedy delivery solution 4 layer pcb design standards speed and effectiveness. normal orders we have improved our processes for production and improved supply chain management, reducing batch delivery times by a whopping 10 days, significantly outpacing the industry standard. Furthermore, in response to immediate needs, we've established express delivery services for smaller batches with an impressive turnaround of only 72 hours. will help ensure your projects get off to a flying start profit from potential market opportunities.