Printed Circuit Boards Printed Circuit Boards (PCBs) are essential components used to power up an array of electronic devices, such as your computer, smartphone or gaming console. The role of these complex parts is crucial to enable one part in a device communicating with another and helping the machine function as intended. In this article today we will go one step further into the world of PCBs and try to understand how they work, WHAT DO THEY ALL AND HOW ARE CONTRIBUTING TO OUR LIVES EVERY DAY..

PCB design and manufacturing is a tedious process involved in creating PCBs. First, a design is carefully made using dedicated software showing all the complex wiring and components that will be required by synthesizers. Then comes a powerful machine that turns this model into an actual PCB, creating the blueprints of designers.

Occasionally a PCB may experience operational complications due to reasons like loosen connections or malfunctional parts. PCB troubleshooting involves examining every connection and components in a systematic way to identify potential malfunctions, so that they can be repaired effectively.

PCB Assembly is a broad term that refers to the practices used during Printed Circuit Board (PCB) design and manufacturing, all of which are done with one sole reason - to realize an electical circuit as effectively as possible. One of these methods is Through Hole Assembly that consists on insertion components through drilled holes in the PCB. Moreover, surface mount assembly is used for those tiny components that do not need the drilled holes making PCB work more accurate and reliable.

Checklist for Prototyping and Testing Process to make sure you are on the right path during product development

One of the critical elements during product development is to prototype and test a PCB design for ensuring smooth transition from conception to realization. Testing the sample PCB in multiple situations can guide us about any defect or inefficiency, so that we make sure this will work perfectly to ultimate device.

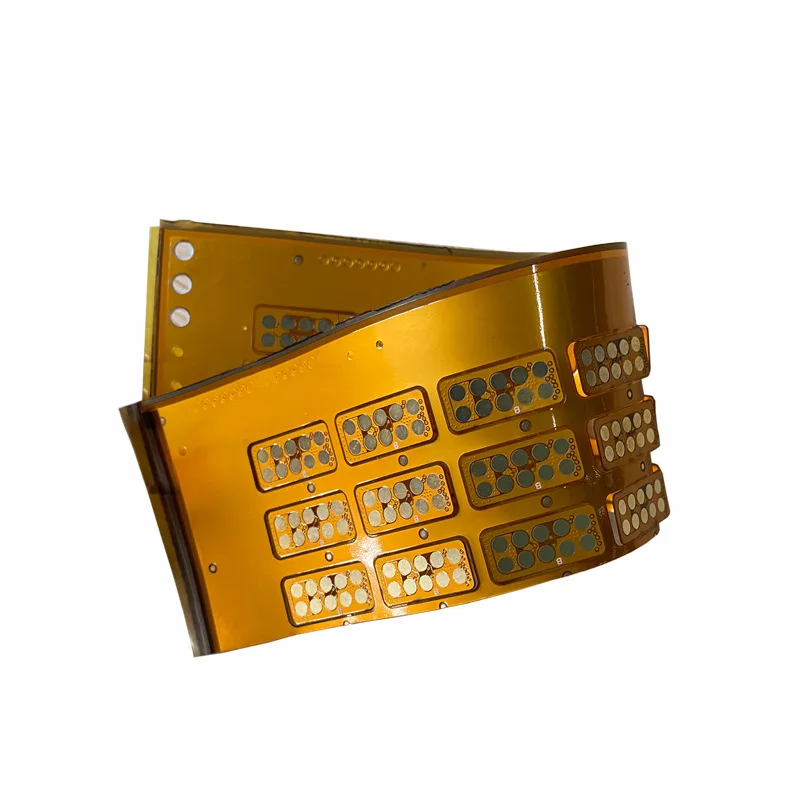

Over the recent years, PCB technology has evolved significantly that it had changed how electronic devices have been capable of functioning. Notable advancements in this category are the employment of flexible PCBs capable to adapt themselves and fit into several dimensions. In addition, 3D printing produces customizable PCBs with special designs as seen above thus improving the functionality of electronic devices.

At its heart, the functions and outcomes of electronic devices are dependent on Printed Circuit Boards which enables them to function seamlessly. Understanding PCB design, troubleshooting and assembling methods helps one in the tumultuous current of electronic product development along with prototyping and testing essentials. Adopting to the ever-evolving PCB technology continuously brings us a step closer towards having more flexible and high performing electronic devices that satisfy our changing demands.

are a PCBA Rapid-delivery solutions provider which sets standards for a pcb and effectiveness. normal orders have improved the production process optimized supply chain management to reduce the time for delivery of batches to just 10 days. This is far ahead of industry norms. Additionally, in wake pressing demands, we've pioneered express services for small batch orders with a remarkable turnaround of only 72 hours, making sure your projects get off to a flying start and take advantage of opportunities in the market.

We'll offer an a pcb service and a determination to produce the greater when it comes to PCBA demands. The SMT mounting is extremely precise and strict quality inspection packaging, into the abilities of DIP plugin processing, and lastly PCBA testing as an important way to make sure production and delivery quality. FCT testing equipment try tested and designed prior to client designed screening points, products, and steps. The rings are constructed to comply with international quality. This guarantees that the final merchandise of exceptional performance as well since longevity.

Established in 2009, Hangzhou Hezhan Technology Co., Ltd. boasts manufacturing facility 6000 square meters is equipped with state-of-the-art cleanrooms tailored for electronics manufacturing. Focusing on research and production electronic surface mounting, company based on vast industry experience provide customers with an all-in-one PCBA solution, and is also moving into small-batch manufacturing and online delivery models.There are around 150 employees employed by company. They a pcb production team around 100 members, an R D department of around 50, sales personnel along with a management staff, and an OEM department that specialized. Hezhan Technology, with an annual turnover close to 50 million Yuan has experienced significant growth in the last few years. The company's compound annual growth rate the last three years is more than 50%, suggesting that it in a rapid expansion phase.

We're well-aware of the specific requirements of each client, therefore, in our one-stop delivery service for PCBA we give great importance to the core value of "customized customer service". Our specialized consultation services are designed to meet the needs of every client. From preliminary concept exploration to specific confirmation of specifications for technical requirements, our expert team works closely together, listening to the requirements of our a pcb, easily adapts processes for service and precisely matches specifications from simple to complex using innovation and technical power.