Ever pondered how these electronic devices function? Imagine a world filled with postage stamp-sized wires and parts, coming together to create awesomeness. But did you realize there was a member of this electronic orchestra who plays quietly in the background. This is really a Blank PCB board.

A PCB (Printed Circuit Board) is a magic carpet for electricity allowing us to perform an mystical dance between components through its tracks. Basically, think of it as a city map for electricity instead of roads for cars.

So, now it comes to the unpopulated part of PCB section Nay, it is but a blank page with endless possibilities for you to craft your electronic opusMMMMM. Blank PCB Board - Because when you have a project or idea involving electronics, the blank PCB becomes your craft canvas where creativity kicks in.

But, why you should use blank PCB boards in your electronic projects to make them top-notch instead of simply commanding a huge target audience from the myriad customers out there?

Adds the Professional Finishing Touch: Your project will look so neat and professional on a blank PCB board, this demonstrates to people that you are very good at electronics.

Customized Fit: Building your own PCB board allows you to cut it to the precise dimensions and shape needed for a project. You need to power what circuits you want (picking and choosing, depending on space & efficiency).

True Reliability: Once all of the components have been soldered onto a PCB board, they are securely connected which in turn reduces the risks breakdowns or fractures over time.

This allows you to populate a very large number of components into the least amount of space and still carry your project with the utmost efficiency.

Printed Circuit Boards Or PCB: A Step By Step Guide To Designing Your Own From Scratch

To guide you through the process of designing and manufacturing your own PCB, follow these steps:

A Basic Schematic Before starting with a design, you need to have in your mind the size of the board, what form will it take and where are going all the circuits.

There are a couple of PCB design tools available in the market - Eagle or KiCad as I used, and others.

If you did everything correctly this will allow your design to be moved on the blank PCB board because of what is printed onto the transfer paper.

Use an iron or a laminator to heat the made paper and then transfer what is inside onto one apad on the copper side of blank PCB board.

Remove excess copper with an etching solution to expose your thoughtfully designed circuitry.

If so, drill mount holes and solder parts to be tiny components.

Explore the given crucial pre-requisites while getting to a PCB board design that make certain your designing goes smooth & becomes successful.

Clean the PCB to eliminate any dirt or powder particles that can prevent some design transfer of etching.

Before drawing a circuit layout make sure the board is thoroughly dry as moisture will cause problems when etching.

Be sure to be safe by using the correct safety equipment when dealing with a solution containing Ethch, and protecting yourself from potential hazards.

Choose a room with good ventilation to reduce the concentration of noxious fumes released when etching.

Here are six of the most common mistakes you should avoid when working on blank PCB board projects:

Check carefully your design whether it is correct and circuits properly connected.

Take your time and solder new wires carefully to retain strong, reliable connections.

Before you commit to your design and finalize assembly, make sure it works as intended communicating with the Bluetooth device.

Equipped with this understanding and reference points, you are now ready to go on a creative path where you can design some unique electronics projects using the blank PCB board. Free your creativity and start the journey of developing something amazing!

are a PCBA rapid-delivery service provider that redefines standards speed and efficiency. We have optimized supply chain management well as improved production processes dramatically reduce the delivery time of batch orders to only 10 days. This is a major blank pcb board over industry standards. Because of the urgent demands we introduced the express service for small batch orders with a turnaround time of just 72 hours. This allows your projects progress quickly, and you can take advantage of the opportunities on the market.

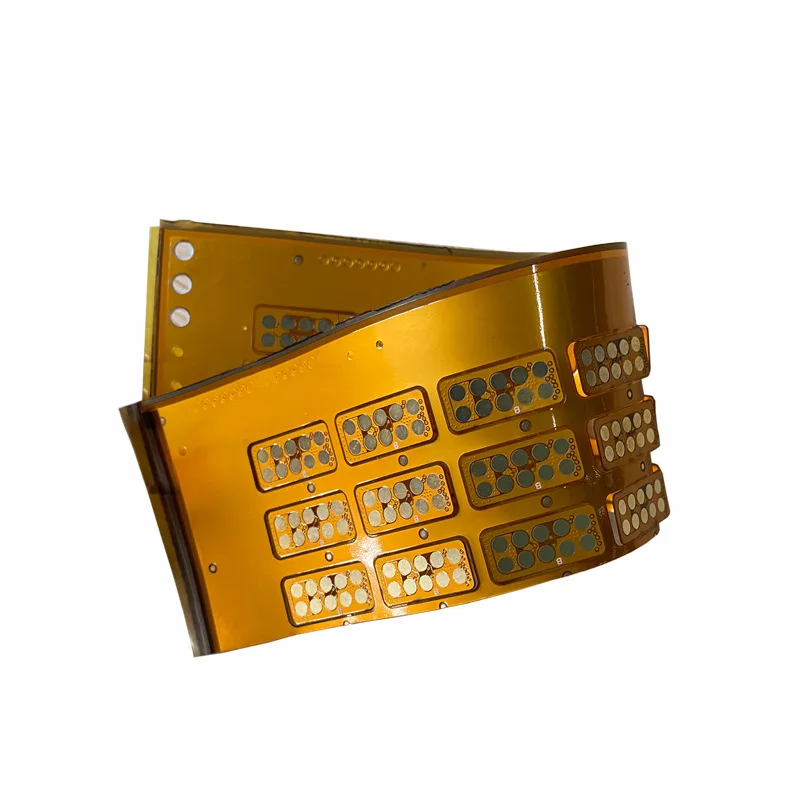

We are going to give you both you and an blank pcb board service commitment to excellence in most your PCBA requirements. With high-precision SMT mounting technologies a strict quality of packaging into the capacity for DIP plugin processing, and finally PCBA testing considering that the crucial approach to make sure that quality of delivery and production, FCT testing fixtures are produced and tested according to customer specified testing points, software and processes. The rings are created to be in accordance with worldwide standards for quality. This helps to ensure that the final product is of superior performance and long-term reliability.

In the PCBA one-stop service, we put a lot of emphasis on the value of "customized services for each client". We offer exclusive, one-on-one professional consultation services to ensure every blank pcb board can receive tailored solutions. Our expert team can provide various solutions, from the initial exploratory phase to confirmation of specifications. They collaborate closely with the customer, adapt service processes flexibly and meet various requirements for projects, basic or intricate, with innovative thinking and technological power.

In 2009, company founded. Hangzhou Hezhan Technology Co., Ltd. boasts facility that covers 6,600 square meters, and equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company specializes electronic surface mounting rely extensive industry knowledge to provide clients with an all-in-one PCBA.The company has a total of 150 employees, which includes a production team about 100, a blank pcb board R D, sales, and management team that is roughly 50 people, as well as a special OEM division. With annual sales revenues in excess of 50 million yuan Hezhan Technology has experienced substantial growth in recent years, has maintained a compound annual growth rate at over 50% for the last three years. This is evidence of a strong expansion phase.