One of the most important aspects to consider when it comes to electronic devices is the use of copper Printed Circuit Boards (PCBs). These copper-layered boards are built into equipment some as simple as smart phones and computers but others embedded in complex medical devices or even system within cars, airplanes or satellites.

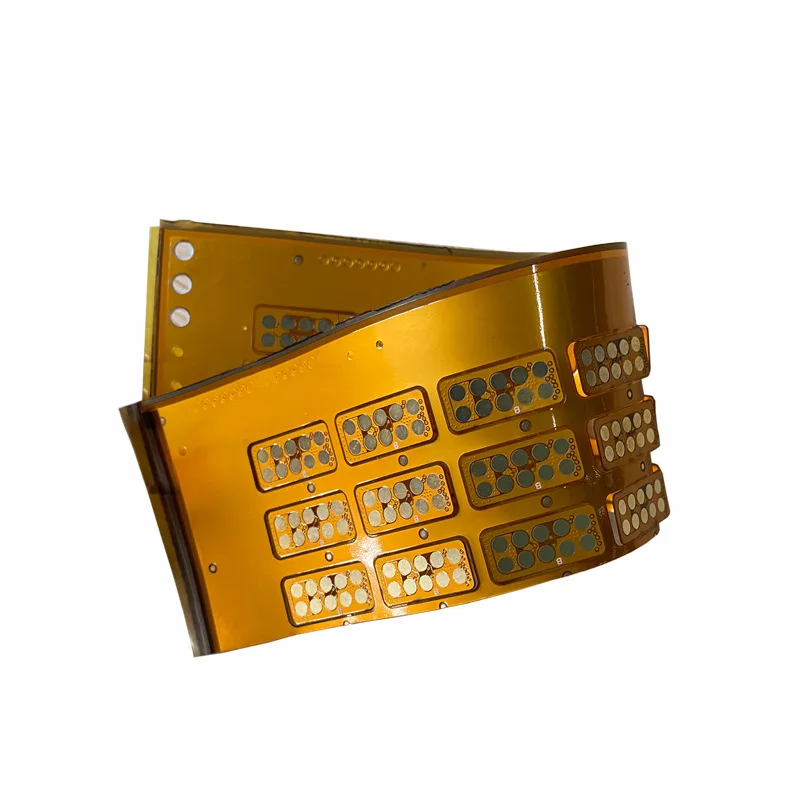

A Copper PCB Board is more or less an ultra-thin layer of copper that gets laminated onto a non-conductive substrate. The copper layer serves as the material from which conductors form, and connects all electronic components together in a continuous, non-corrupted conduit. This layer of copper simply lets the electricity pass through it, which helps to ensure better and efficient working of your electronic device.

One of the main benefits to use copper in PCB boards are obviously its intrinsic conductivity properties. Such properties then help to limit the electrical resistance during conductivity making it possible for signals within electronic devices to flow with lesser loss and influence improving ion cmponents overall performance. Beyond this, copper is great at conducting (good and bad) heat energy from compenents really well so it manages to keep other parts of the device cooler helping with longevity. On top of that, copper is resistant to solderability and chemical properties as well which makes it tough-affiliated usable material in the PCB boards.

There are various aspects to consider and best practices to follow when designing a Copper PCB Board, so it remains functional. The provision of space to allow the current through and minimize parasitic capacitance using suitable trace width and spacing is essential. The use of high-quality materials, such as copper, substrate and solder mask material are important but also the aspects like signal integrity (power domain), ground plane distribution in pcb files and power distribution for noise reduction must be consider when designing a reliable operation circuit.

Fabrication and Assembly of Copper PCB Boards require quality control at every stage because if you error on one it will create a mess up in the other steps processes. Most significantly, make sure to choose a well-known and established PCB manufacturer that follows standard processes with stringent quality assurance methods in place. Testing Proper testing throughout production at every stage and before shipment is key to detecting any faults or issues early. Moreover, the use of automation and software tools for design minimizing manufacturing timeframes which play a vital role in reducing Copper PCB Boards costs.

So Copper PCB Boards are not only indispensable in all types of electronic devices but also necessary for high-frequency applications. So, if you have an ambition to design implement your electronic dreams through the best quality of PCBs then CopperPCB Boards are what will help but choose wisely concerning the thickness and layers plus consider manufacturing by applying golden rules with full coverage testing grounds this assures reliability all time.

With the PCBA one-stop service, we place great importance on the importance of "customized service for each customer". Our specialized consulting services are adapted to each copper pcb board. From preliminary concept exploration to the precise technical specification confirmation, our expert team works closely together, listening to customer requirements, and flexibly adapts processes for service, and accurately matches various needs from basic to complex with innovation and technical expertise.

specialize providing a one-stop PCBA quick delivery service that copper pcb board standards speed and efficiency. orders that are standard we have streamlined our processes production and improved supply chain management to reduce batch delivery times to a staggering 10 days, significantly outpacing industry standards. Moreover, recognition of urgent needs, we have pioneered express services for small batches with an impressive turnaround of only 72 hours, making sure the projects run smoothly and take advantage of market opportunities.

In 2009, company founded. Hangzhou Hezhan Technology Co., Ltd. boasts facility that covers 6,600 square meters, and equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company specializes electronic surface mounting rely extensive industry knowledge to provide clients with an all-in-one PCBA.The company has a total of 150 employees, which includes a production team about 100, a copper pcb board R D, sales, and management team that is roughly 50 people, as well as a special OEM division. With annual sales revenues in excess of 50 million yuan Hezhan Technology has experienced substantial growth in recent years, has maintained a compound annual growth rate at over 50% for the last three years. This is evidence of a strong expansion phase.

We're specialized in delivering a solid dedication our customers to copper pcb board and service for their PCBA one-stop service for delivery requirements. The SMT mounting is highly precise and strict quality packaging, to the process ability of plunge plugin processing, as well as PCBA testing being a vital step to make sure high-quality production and distribution, FCT testing equipment is made plus tested relative to your client designed testing points, programs, and steps. The rings are created to meet international quality. This means that the things delivered are of outstanding reliability plus long-term performance.