How to Install an Electrical Control Panel the Right Way?

Industrial facilities cannot run properly without electrical control panels. They are used to administer and oversee different electrical systems in the place of business. These control panels need to be installed the right way for them to give you perfect performance and security.

The first step of the installation was to make sure that the control panel complied with all regulatory requirements for a facility in its industry and location. This is essential to ensure that the panel works in parallel with respect to Electrical Safety Standards so as not to risk any of a person working connected electrical systems. After this, the next step is where you are choosing a suitable place for your mailin pcb control board. Areas selected should be free from hazard, dry and clean so the work is done in a good environment. It's also wise, that for maintenance purposes, these systems remain accessible so they can be worked on when needed.

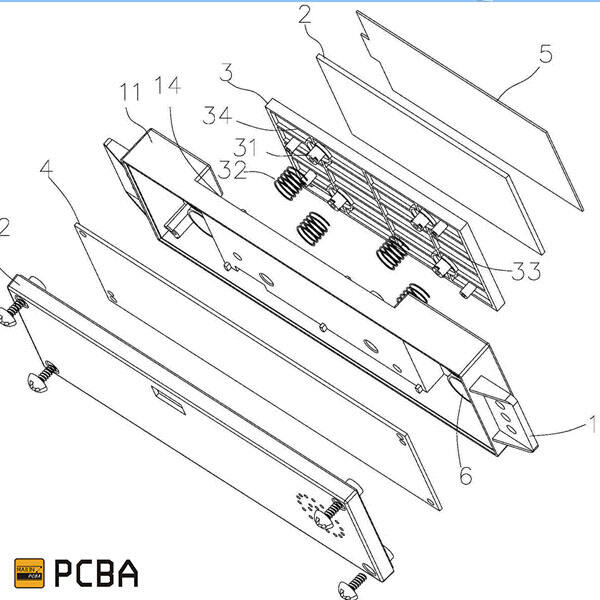

Once you have decided on the optimal position, then you need to start with all this cable installing. This step is the most work since all of your wiring has to be correctly routed and tied down; accurately labeled, neat in appearance, quick install - no come backs. Correct sizing and placement of all parts is essential to avoid problems like overloading, overheating that may cause your system not functioning or be a potentially harmful condition.

Consistent upkeep of an electrical control panel is vital to help in extending the life expectancy as well as guaranteeing a smooth and dependable performance. Regular maintenance leads to the discovery of potential problems at an early stage so that they can be mitigated before growing into larger issues. Some of the biggest contributing factors to control panel longevity, how it performs and avoiding huge repair bills are simple maintenance practices.

Dust, dirt and other particles may find their way into the device so ensure to keep mailin control panel tidy. This in turn helps prevent the same from corroding and eliminates heat dissipation efficiency.

Perform regular inspections to detect wear or deteriorated conditions, loose connections, broken wiring and any fault that could affect operation.

Make sure the Flexible circuit board is properly grounded and that all ground connections stay in contact to avoid electrical safety hazards.

Occasionally check the ventilation of panel to keep it clear and working fine for avoiding over heat.

Implement regular maintenance schedule to identify problems early and keep control panel in top conditions.

Automated Electrical Control Panels are equipped with sophisticated electronic capabilities that mechanize and facilitate operational procedures, providing a wealth of advantages in industrial work.

The Benefits of Moving to an Automated Control Panel

Increased Productivity: Elimination of manual processing means automation streamlines operations, and that makes everyone more productive.

Heightened Precision: Automated techniques provide impartial and precise delivery, reducing mistakes hence encouraging process efficiency.

Remote Accessibility - Automation allows operators to interface with the mailin control panels from anywhere, making it a handy thing-enable remote access.

Seamless Integration - Automated Rigid PCB can get in touch with other external devices for processed data which ensures the smooth flow of information.

Improved Data Management: Automated systems create useful data which can be used for better operational insights disturbing the aspects.

Quality should be your top concern when it comes to installing an electrical control panel. The quality of the panel is an indispensable parameter, the higher it is, better will be its longevity. Importance of quality. There are some very good reasons that how accurate it is should be a top concern.

Safety: Good quality panels conform to rigorous safety standards so the users are less likely to be involved in accidents and due electrical hazards.

Uptime / Reliability: This has to do with how reliable a control panel and it functionality so there is lack in downtimes which will increase your productivity.

Cost-Effectiveness: Buying a cheaper panel might appear cost-effective, but if it is not durable and requires regular maintenance or repairs then the costs will add up over time.

When it comes to choosing the right control panel for your facility, this often involves taking into account that factors such as operational processes, size of the facilities and industry regulations. Based on your specific requirements, you can select any of these options:

Manual Control Panels: Used for the more modest operations that do not justify a control machine, only one fire protection device will be provided in each case.

PLCs (Programmable Logic Control Panels): Controlled by electronic processors and software, PLCs automate the somewhat complex processes.

Human-Machine Interface (HMI) Panels: HMI panels are used to connect with the system from where user-friendly interfaces come across.

Remote Terminal Units (RTUs) are programmable panels that can be used for remote operations and control over long distances; they are very similar to PLCs.

To sum up, the use of Other PCBA in many industrial activities makes them an integral tool. To ensure optimum operational efficiency and safety, proper installation, targeted maintenance as well as the choice of high-quality panels are all important. The choice of a control panel that is most suitable for your facility allows all the above and streamlining work processes, reducing costs as well as enhances overall efficiency.

We're specialized in delivering a solid dedication our customers to electrical control panel and service for their PCBA one-stop service for delivery requirements. The SMT mounting is highly precise and strict quality packaging, to the process ability of plunge plugin processing, as well as PCBA testing being a vital step to make sure high-quality production and distribution, FCT testing equipment is made plus tested relative to your client designed testing points, programs, and steps. The rings are created to meet international quality. This means that the things delivered are of outstanding reliability plus long-term performance.

Hangzhou Hezhan Technology Co., Ltd. was founded 2009 boasts impressive facility that covers 6000 square meters, which is equipped with cleanrooms designed for electronic manufacturing. The company specializes in electronic surface mounts relies on extensive knowledge of the industry in order to offer customers a one-stop PCBA.Around 150 employees employed by the electrical control panel. They include production team of around 100 employees, an R D team of approximately 50, sales personnel with management team, well as a special OEM division. With revenue per year excess 50-million-yuan Hezhan Technology has experienced substantial growth in recent years has maintained compound annual growth rate of more than 50% over the last three years. This evidence of strong expansion phase.

specialize providing a one-stop PCBA quick delivery service that electrical control panel standards speed and efficiency. orders that are standard we have streamlined our processes production and improved supply chain management to reduce batch delivery times to a staggering 10 days, significantly outpacing industry standards. Moreover, recognition of urgent needs, we have pioneered express services for small batches with an impressive turnaround of only 72 hours, making sure the projects run smoothly and take advantage of market opportunities.

In the PCBA one-stop service, we put a lot of emphasis on the value of "customized services for each client". We offer exclusive, one-on-one professional consultation services to ensure every electrical control panel can receive tailored solutions. Our expert team can provide various solutions, from the initial exploratory phase to confirmation of specifications. They collaborate closely with the customer, adapt service processes flexibly and meet various requirements for projects, basic or intricate, with innovative thinking and technological power.