Manufacturing PCBs can be a laborious task. It Is Important to Make Prototype Before Making Final Product Think of a prototype as you would for an example or model that demonstrates what the last product will look like and function. Making Prototypes can be time consuming, so everyone needs fast ways to get your PCB prototypes and this really helps. In this text, we are going to discuss how you can get your PCB prototypes without a hassle and in no time.

Advantages of fast prototyping:Making a quick example for your product. This is particularly important in the case of industries as fast-paced and regularly changing as electronics. Consider, for instance, that your product might be out of date by the time it gets to market if you spend too long over its completion. Rapid prototyping: To keep our products current and attractive to customers who want state of the art technology. Fast prototyping further helps make the outcome of your work more meaningful.

So, if you have a project which needs the design of PCB prototype as soon possible so there are options available. Most electronic devices including smartphones, computers and tablets contain Printed Circuit Boards (PCBs). Fashioning PCBs, but can be challenging as they must apply some sort of precision and care. As we know, one reason why PCB is used in so many electronics devices because printed circuit boards can be made into test circuits quickly. That way, making sure your project stays on time and gets completed by deadline.

When you need a prototype in rapid-time, quick fixes are great to reach the MVP. Prototyping a PCBs quickly can be an if-not-a-need then at least a huge boon to get the project along, especially when timelines are tight. Every minute is a bonus when time has flown! Instant fixes help you in building the prototype of a PCB within very less time so that your project can lead to its next phase without any delay. This speed can make or break your objectives.

If you want a PCB prototype in the shortest possible time, then fast solutions are what should be considered. For projects that need to be turned around quickly, a quick solution is ideal. They can make a prototype for you in no time, and that helps with getting your working-cadence spinning immediately without pause. Quick answer: these are also a boon if you need to churn out many PCB prototypes in quick succession. E.g. : If you are researching on different design/ features then having the facility to create many prototypes quickly is an advantage

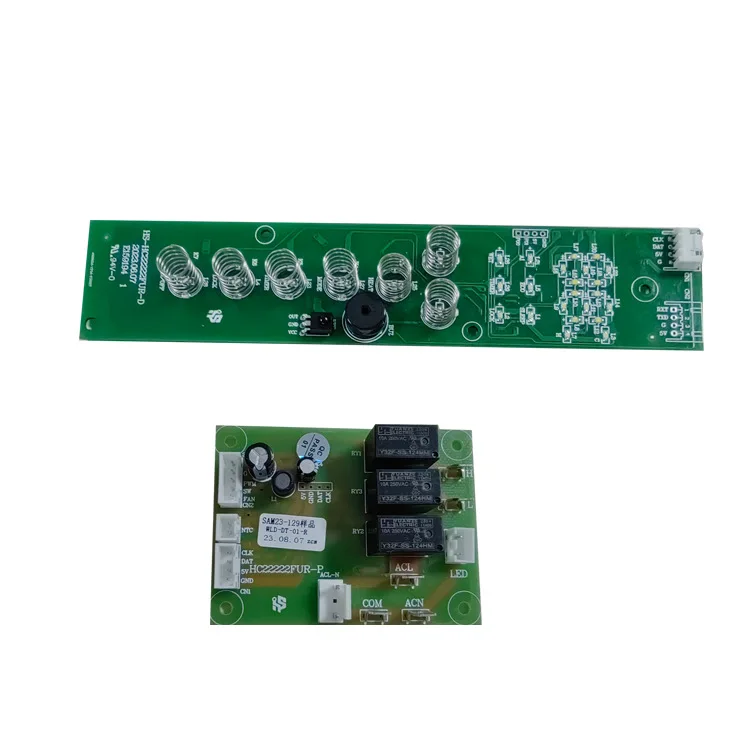

Established in 2009, Hangzhou Hezhan Technology Co., Ltd. boasts manufacturing facility 6000 square meters is equipped with state-of-the-art cleanrooms tailored for electronics manufacturing. Focusing on research and production electronic surface mounting, company based on vast industry experience provide customers with an all-in-one PCBA solution, and is also moving into small-batch manufacturing and online delivery models.There are around 150 employees employed by company. They fast turn pcb prototype production team around 100 members, an R D department of around 50, sales personnel along with a management staff, and an OEM department that specialized. Hezhan Technology, with an annual turnover close to 50 million Yuan has experienced significant growth in the last few years. The company's compound annual growth rate the last three years is more than 50%, suggesting that it in a rapid expansion phase.

specialize providing a one-stop PCBA quick delivery service that fast turn pcb prototype standards speed and efficiency. orders that are standard we have streamlined our processes production and improved supply chain management to reduce batch delivery times to a staggering 10 days, significantly outpacing industry standards. Moreover, recognition of urgent needs, we have pioneered express services for small batches with an impressive turnaround of only 72 hours, making sure the projects run smoothly and take advantage of market opportunities.

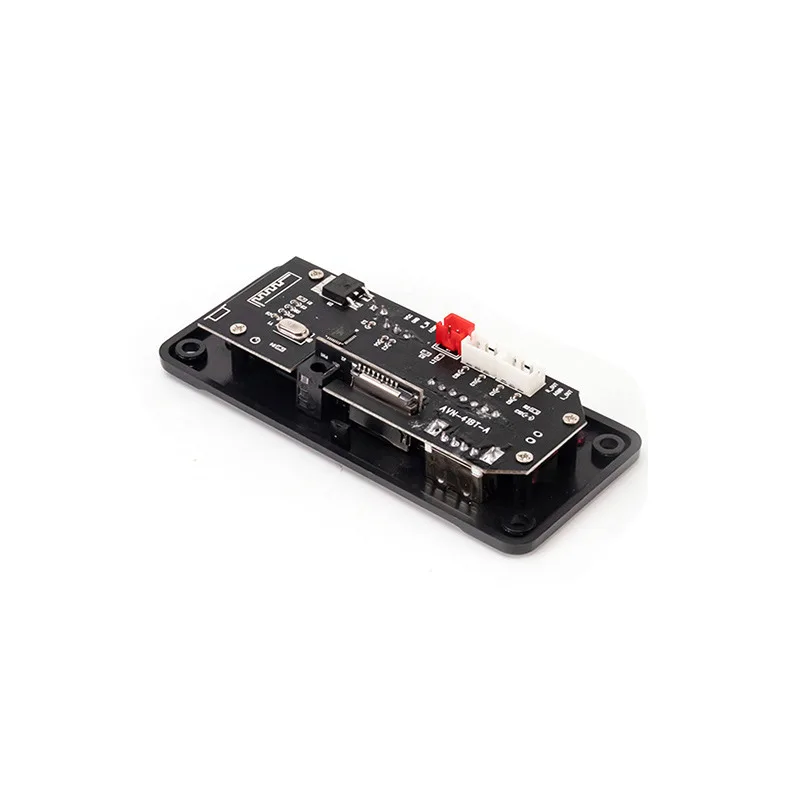

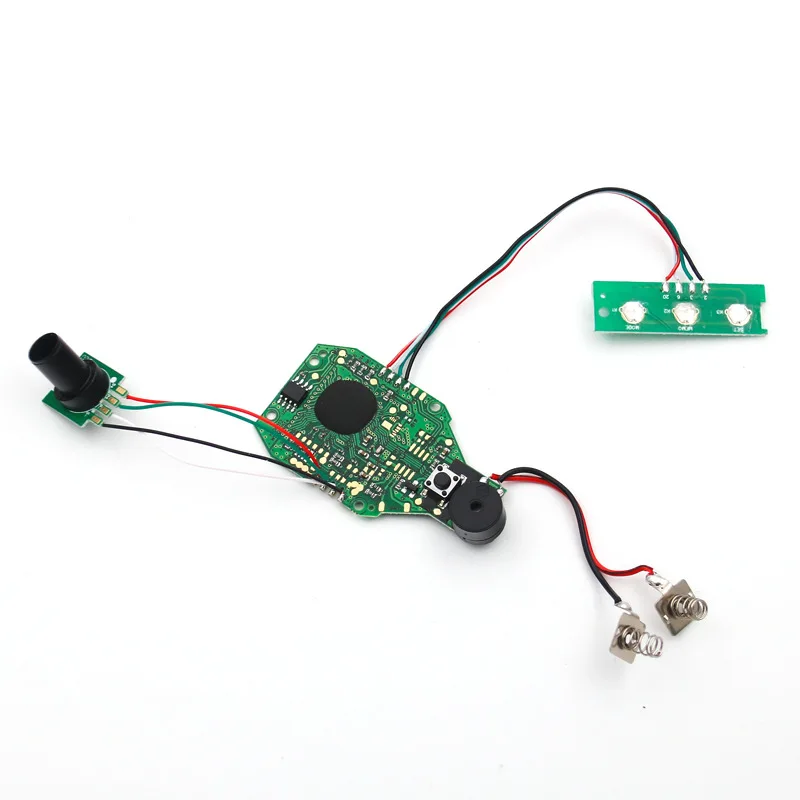

we are dedicated to supplying the fast turn pcb prototype and customer service to meet your PCBA single-stop requirements delivery. The FCT testing fixture has been developed in accordance because of the customer's test points, steps, and programs. This includes precise mounting, rigorous quality assessment packaging, and plunge plug-in process. The rings are made to stay line with international standards for quality. It will help to ensure that the things delivered are of outstanding performance and long-term durability.

In the PCBA one-stop service, we put a lot of emphasis on the value of "customized services for each client". We offer exclusive, one-on-one professional consultation services to ensure every fast turn pcb prototype can receive tailored solutions. Our expert team can provide various solutions, from the initial exploratory phase to confirmation of specifications. They collaborate closely with the customer, adapt service processes flexibly and meet various requirements for projects, basic or intricate, with innovative thinking and technological power.