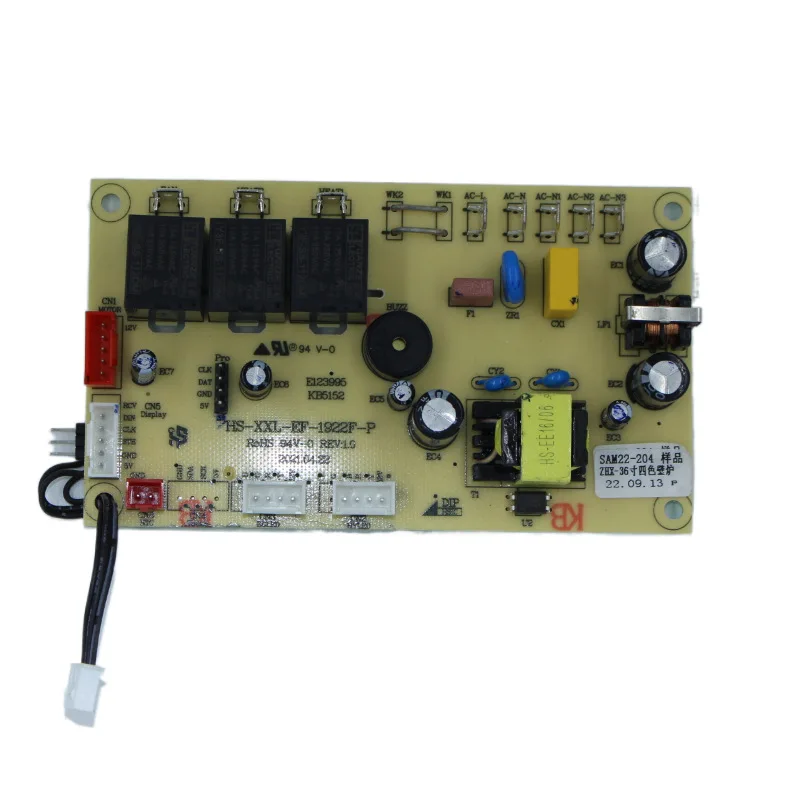

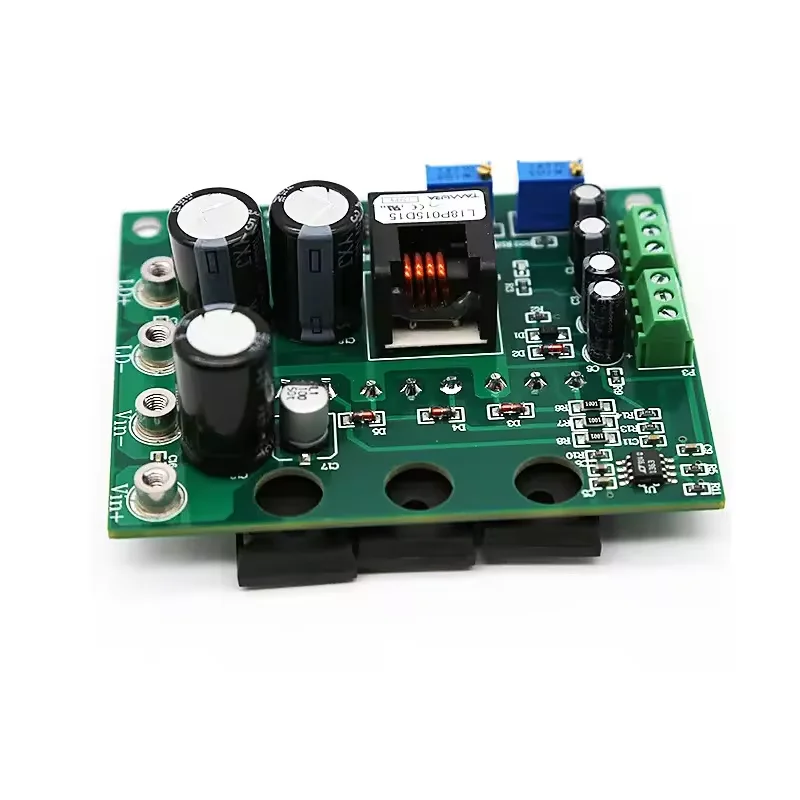

An individual Integrated circuit (ic) board popularly known by the name of a printed wiring board, is primarily small boards holding various mini tools together that generally work fine to run your base for all type's electronics gadgets. These devices are made up of components such as transistors, resistors and capacitors that ensure the device works correctly. Transistors for example are used to control the flow of electricity across the board, a role that is vital in protecting other components of your device from getting damaged.

There are many ways to produce IC circuit boards. A common one is surface-mount technology, where electronically components are stuck on top of the botoanda The way Fixedly installed with a new drilling hole as traditionally done. This innovative method caught on because it allowed boards to be developed smaller and more compact which helped accommodate the fast-paced technological changes.

Best Practices and Recommendations for Board Development

There are specific guidelines and best practices which are to be followed through on the development of ic circuit boards. The basic rule is that it should contain enough space between traces, the lines on the board to transfer electricity from one part of a circuit cleanly without any loss. The design consideration shown above can lead to short circuits or else noise, which in turn may interfere with the performance of the device. Keeping the board clean and free of debris that might affect its components is also important to ensure proper functioning.

One of the most common problems with ic circuit boards is overheating which crypts into a situation where parts will be damaged or end up not working on your board. The insertion of a layer with the heat sink (the material used to absorb and dissipate excess temperature that is detrimental for proper operation) into printed circuit board will help alleviate this problem. Second, bad connections between the components need a very detailed verification process to ensure that everything is connected as needs and moreover traces are aligned properly on the board.

Latest PCB Technologies - Innovations and Trends

Technological developments have driven ic circuit boards towards miniaturization as well as higher power capabilities. One remarkable trend is the creation of wearables-focused boards, such as those for smartwatches and fitness trackers; this involves extremely small form factors with unified procesor/memory/storage solutions designed to fit seamlessly into devices like these. The advancement of flex circuit boards that can be bent and folded, thus adapting to the oddball shape you need is also a game changer for developing nontraditional looking devices yet.

Ic circuit boards are included as part of the interior structure to play a key role in many electronic devices used daily, eg. smartphones, computer and car etc. If these boards were removed, the devices would be rendered almost useless. Major companies like Apple and Samsung have been investing in the R&D of ic circuit boards for better efficiency as well as performance. One of the Companies that has created an extremely effective use-case using Gecko Robotics which essentially designed a Military grade ic circuit board to detect potential problems in industrial equipment thus avoiding any failures and minimized downtime for 100s of thousands per day bucks on cost centre by companies.

Basically, if we consider about electronics the ic circuit broads plays very important role in it. These boards are designed to operate efficiently and steadily as a result of the various combination techniques, utilizing best practices. As technology continues to advance, we look forward to seeing more of the innovation and improvements in ic circuit boards that will mold the future function of ones electronic devices.

We'll offer an ic circuit board service and a determination to produce the greater when it comes to PCBA demands. The SMT mounting is extremely precise and strict quality inspection packaging, into the abilities of DIP plugin processing, and lastly PCBA testing as an important way to make sure production and delivery quality. FCT testing equipment try tested and designed prior to client designed screening points, products, and steps. The rings are constructed to comply with international quality. This guarantees that the final merchandise of exceptional performance as well since longevity.

In 2009, company founded. Hangzhou Hezhan Technology Co., Ltd. boasts facility that covers 6,600 square meters, and equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company specializes electronic surface mounting rely extensive industry knowledge to provide clients with an all-in-one PCBA.The company has a total of 150 employees, which includes a production team about 100, a ic circuit board R D, sales, and management team that is roughly 50 people, as well as a special OEM division. With annual sales revenues in excess of 50 million yuan Hezhan Technology has experienced substantial growth in recent years, has maintained a compound annual growth rate at over 50% for the last three years. This is evidence of a strong expansion phase.

We are aware of the individual needs of each ic circuit board, why, in the one-stop delivery service of PCBA we give great importance to the principle of "customized customer service". We provide exclusive one-on-one professional consultation services to ensure each customer receives individualized solutions. From initial concept exploration to precise confirmation of technical specifications Our expert team works closely together, patiently listens to customer requirements, and flexibly adapts the service process and efficiently matches needs from basic to complicated with creativity and technical rigor.

are a PCBA Rapid-delivery solutions provider that redefines standards speed efficiency. standard orders, we have streamlined production processes and optimized supply chain management, reducing the delivery time of batches by a ic circuit board10 days, significantly outpacing the industry standard. In recognition of urgent requirements, we developed the express service for small batch orders, which have a turn-around time of only 72 hours. This allows your projects to are able to move quickly and benefit of market opportunities.