Electronics are a wonder but this wouldn't be possible without each of the various parts working together to make sure that electronics runs as needed. It is consisting of very important part so call IC PCB. The letters IC are an abbreviation for Integrated Circuit, the latter word meaning that it is a small electronic circuit combined of different components. A Printed Circuit Board (PCB) is a flat board that holds and connects these electronic elements. To combine, IC PCBs are small boards that include many electrical components for use in a variety of devices (including computers and smartphones) as well even some household appliances we utilize everyday.

IC PCBs have brought really big changes to the electronics industry in many aspects Electronic devices were bigger and more cumbersome, less efficient (less good) before the invention of IC PCBs. Now, IoT devices can be smaller and more powerful because of IC PCBs. Nowadays it is a big edge because that why we are able to put so much technology in smaller gadgets. Then, these devices are more portable; we can take them with us and use them in our everyday life so they become convenient for individuals.

They also make using IC PCBs when designing circuits quite beneficial, which helps to simplify the work and improve its efficiency. For starters, one small PCB has the potential to host a multitude of electronic components. Engineers can therefore create elaborate circuits that hardly take up any physical real-estate. This really lowers the cost of production much which in turn leads to affordable devices.

Secondly, IC PCBs are far more dependable than circuits that have been made without the use of them. This also implies they normally carry out a lot better and last for some time. IC PCB, which has a special material that allows heat absorption from the components of baord placed on it. The heat generated in these processes can often cause the electronic apparatus to become overheated and dull. But the special material on the IC PCB prevents those parts from getting too hot and subsequently breaking down. For that reason, tools with IC PCBs have a lot more life expectancy and job even more dependably for individuals which is greatly advantageous.

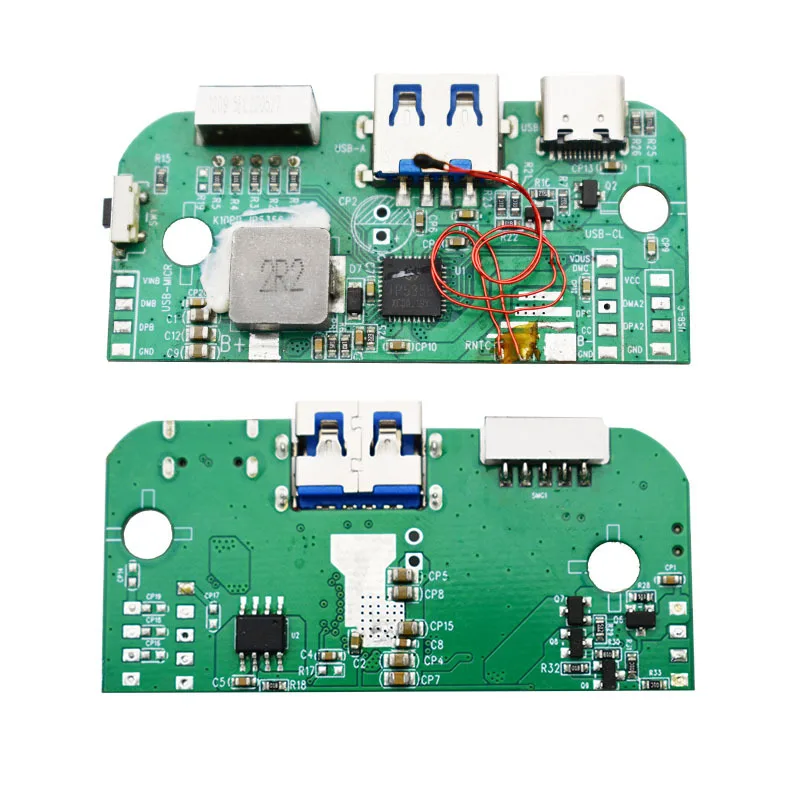

How well IC PCBs work depends widely on how they are made. How IC PCB is made: The path the copper takes on an IC board begins as a thin layer of copper foil placed over a fiberglass. This copper foil is required because this will make the connections into circuit. Next, is a special film called photoresist then another lining with the circuit design placed over it. The film is exposed to a light; this would facilitate the plan being transferred onto the photo resist material.

The board is then placed carefully in a solution that erodes away the unprotected copper shielded only by photoresist. This is important, because it sets up the needed connections and separations to make a circuit work as intended. At last, the different electronic components are attached to this board through a procedure called soldering. Finally, after these steps are performed the IC PCB can be used in an end device.

With the improvement and advancement in technology, IC PCBs can be use for a variety of facilities. This sector also expects to see more IC PCBs used in wearable technology (fitness trackers and smartwatches). Such devices need light, tiny parts to work as they should-something that only IC PCB can offer. If more and people start using these daily while exercising, wouldn't the requirement simultaneously increase as it's getting quite popular?

we are dedicated to supplying the ic pcb and customer service to meet your PCBA single-stop requirements delivery. The FCT testing fixture has been developed in accordance because of the customer's test points, steps, and programs. This includes precise mounting, rigorous quality assessment packaging, and plunge plug-in process. The rings are made to stay line with international standards for quality. It will help to ensure that the things delivered are of outstanding performance and long-term durability.

Hangzhou Hezhan Technology Co., Ltd. was established 2009 and has an impressive manufacturing facility covering 6,600 square meters of space, equipped cleanrooms specifically madefacilitate electronic manufacturing. The company specializes electronic surface mounting and rely on extensive knowledge the industry in order to offer customers complete PCBA.company employs around 150 people by the company, which includes production team of around 100 people, a R D team of ic pcb50, sales personnel with management team, as well as an OEM division that is special. Hezhan Technology, an annual revenue more than 50 million yuan seen significant growth in last couple of years. The compound annual growth rate the last three years is greater than 50%, which indicates that it is in a rapid expansion phase.

With the PCBA one-stop service, we put a lot of emphasis on the value of "customized services for each client". Our professional consulting services are adapted to every ic pcb. Our experienced team can provide a wide range of solutions, from the initial idea exploration right through to specification confirmation. They work closely together to listen to the needs of the client, adapt service processes flexibly, and match various demands for projects, no matter how basic or intricate, with technological innovation and the latest technology.

We're a PCBA rapid-delivery solution provider that redefines ic pcb speed. orders that standard we have streamlined manufacturing processes improved supply chain management, reducing the duration of delivery for batches by a whopping 10 days, significantly outpacing industry standards. In recognition of urgent requirements, we pioneered the express service for small-scale orders, with a turnaround time of only 72 hours. ensures your projects are able to move quickly and benefit of opportunities in the market.