An Inverter PCB or in other words as referring to the full term, an inverter printed circuit board is a great part that helps control power of many electrical devices including air conditioners (ACs), refrigerators and even cars. In The Mystic World Of Inverter PCBs Or What They Do And Why?

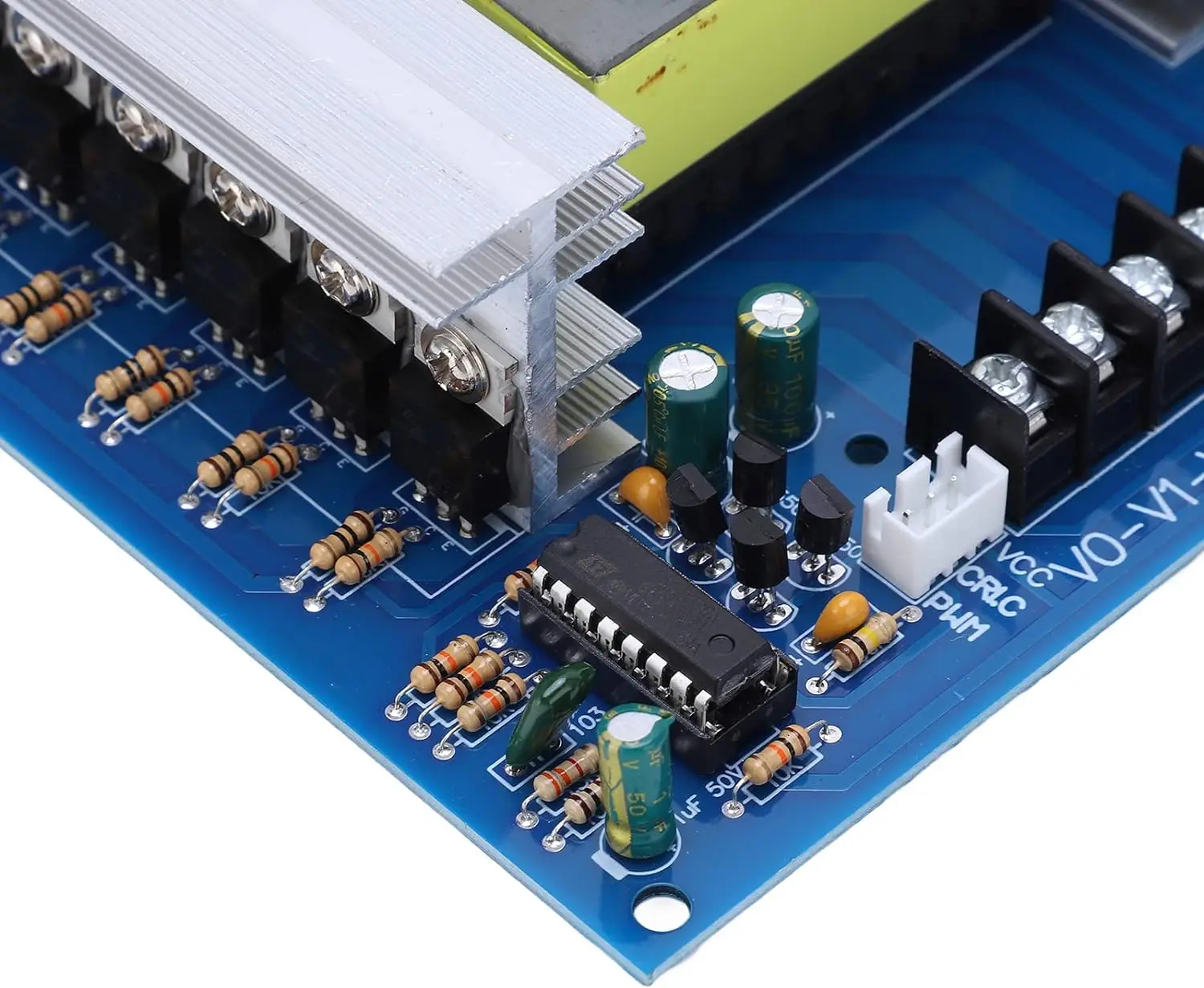

In inverter PCB is principally a power converter, which means it turns dc electricity into ac electricity. This is a pivotal procedure since numerous electronic devices such as Air conditioners require AC to function smoothly. The inverter PCB ensures that a device gets the type of power it requires for smooth operations.

However, fine tuning power levels to deliver just the right amount of electricity for optimum performance is another solution.

Apart from changing power types, the inverter PCBcharger features one more amazing property that it controls how much of the output current is charged to a device. Budget- Some electrical appliances, i.e., refrigerators or washing machines draw a higher level of power at particular times depending on their working cycle. At this point, the inverter PCB serves to provide just enough power for the device to work at its best.

Energy saving is one major feature made possible by the inverter PCB, which makes it a product to look out for. The inverter PCB can regulate the power flow frequency, which will prevent unnecessary use of electricity and thus energy consumption as well - it helps you save money on your electric bill.

Due to further adaption of technology, they are no longer confined service in general devices. Inverter Boards are now widely used in Cars, and Solar panels. Automobiles are now assisted by Inverter PCBs for effective fuel efficiency and Solar Panels attached to these boards gives efficient storage as well usage of solar energy.

How To Care for Your Inverter PCB Longevity

It is essential to give right care and persistent for your inverter PCB so as to save the performance of it. This includes the maintenance of a clean, dry board that is free from any particles such as sawdust or dust on and around it; checking for proper installation; secure all connections to motors other devices with appropriate wire nuts. Your key to extending the life expectancy of your device is simply by inspecting it for wear and tear regularly, as well as storing it in a cool dry place.

On rare occasions, there can usually be a common problem with inverter PCB such as overheating and powers fluctuations. Some common troubleshooting tips can troubleshoot these issues When it comes the overheating issue, adjusting input power and getting ventilation are two basic steps. When experiencing power stability issues, proper checks to connections and distance from the source can assure it will not be an issue.

Simply Put - these Inverter PCBs modules are Crucial For Electronics Devices to be able to control power, save energy and work for long. Inverter PCBs embrace proper maintenance practices, and prompt attention to any problems that arise can help ensure the long-term functionality of electronic devices.

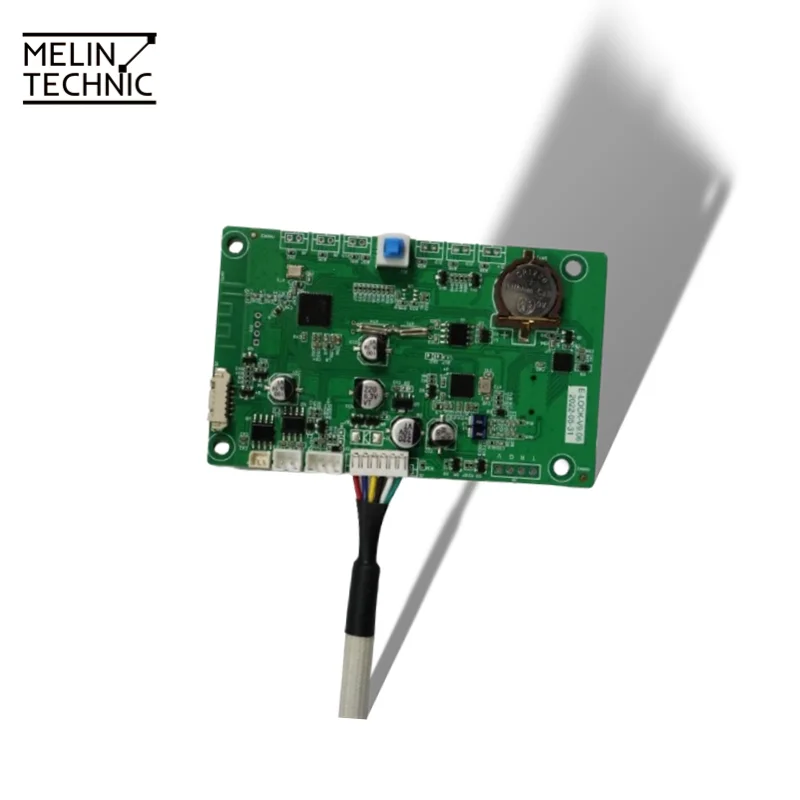

We're a PCBA supplier a rapid-delivery system that set new standards speed and effectiveness. have improved our supply chain management as well as streamlining our production processes to reduce batch delivery time to only 10 days. This is a huge inverter pcb over industry norms. Additionally, wake of pressing demands, we've created express services for small batches, which have a remarkable turnaround time of just 72 hours, which will ensure that the projects run smoothly and take advantage of opportunities in the market.

We're well-aware of the specific requirements of each client, therefore, in our one-stop delivery service for PCBA we give great importance to the core value of "customized customer service". Our specialized consultation services are designed to meet the needs of every client. From preliminary concept exploration to specific confirmation of specifications for technical requirements, our expert team works closely together, listening to the requirements of our inverter pcb, easily adapts processes for service and precisely matches specifications from simple to complex using innovation and technical power.

We are specialized in inverter pcb a solid consignment quality and service for your PCBA single-stop requirements for delivery. Linked to the highest-quality SMT mounting technology rigorous quality inspection packaging, into the capacity for DIP plugin processing, and PCBA testing because a vital process to ensure the manufacturing and delivery quality. FCT testing fixtures are created and tested according to customer created testing points programs steps. Each ring is rigorously adheres to international quality, that means that those items delivered is of high end and endurance that was long-term.

Founded in 2009, Hangzhou Hezhan Technology Co., Ltd. boasts factory spanning 6000 square meters and is equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company leader research production electronic surface mounting, company based on its vast industry experience to provide customers with all-in-one PCBA solution, as well as expanding into small-batch production delivery options online.company currently employs around 150 employees, which includes production team approximately 100, a R D, sales, management inverter pcb of about 50 employees, as well as a specialized OEM division. Hezhan Technology, an annual turnover of close to 50 million yuan, has experienced significant growth last few years. company's annual compound increase over past three years more than 50%, suggesting that it is a rapid expansion phase.