Multi-Layer Printed Circuit Boards, or PCBs for short are boards that help connect various constituents of an electronic device, also the Mailin's product such as rgb led pcb board. It is very important in technology. Multi-layer PCBs have lots of layers all stacked on top one another; whereas single layer PCBs are just that – they only contain a solitary layer. This design lets developers hook up anything they want to more pieces that would not have found a place on just one layer. These additional connections are why multi-layer PCB offers far more advantage over single-layer types.

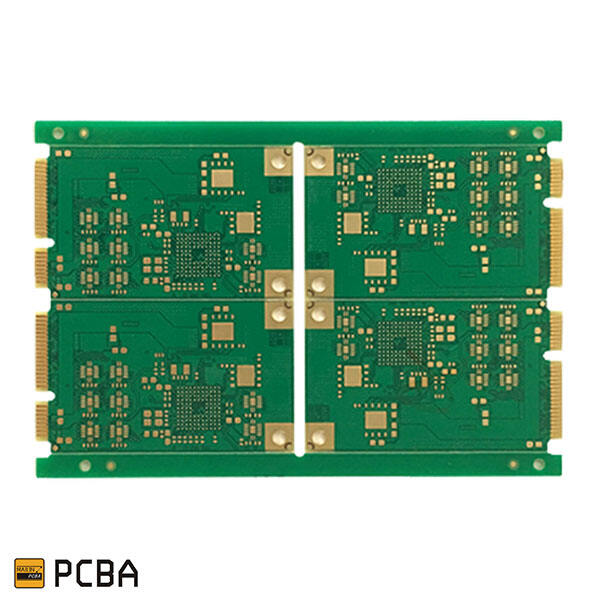

This is one of the advantages to multi-layer PCBs in general as they are able to handle a lot more detail and levels of complexity. They can also pack more electronic components into taking up less space because of their multiple layers. This is handy because it enables the creation of much smaller and sleeker electronic devices. For instance, multi-layer PCBs are in use inside stuff that we come across a lot such as: Mobile phones The vast majority of modern gadgets/Laptops Handheld gaming consoles They help make sure that everything is able to interoperate effectively even with little room.

The multi-layer PCBs are also more reliable, as well as the copper printed circuit board produced by Mailin. The more layers there are, the longer circuits wiring can be routed and connected between separate areas. By this is, even if one way fails or breaks out of order there are many ways arranged for the electricity to run away and get through. It offers a level of redundancy which makes the PCB more reliable. Therefore, multi-layer PCBs are widely used in rather essential electronic devices for which performance cannot be compromised at any cost such as medical equipment and safety systems.

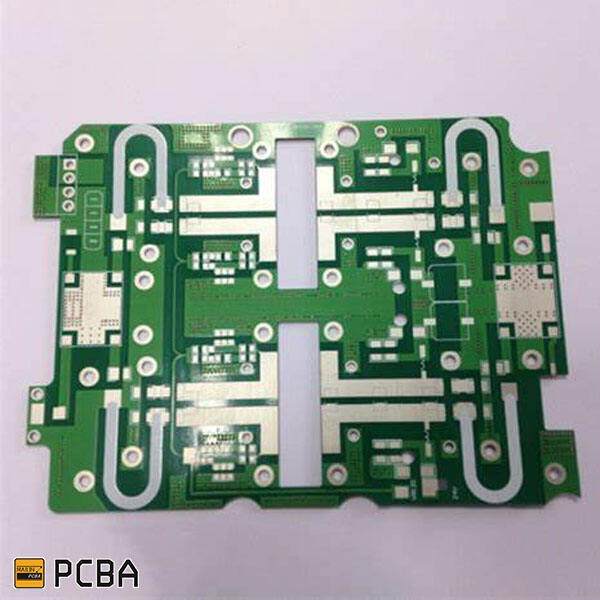

The production is incomprehensibly convoluted for multi-layer PCBs and have a few layers. This begins with printing the layers to a special board material called substrate. Following this, workers bore holes for the electronic components which are fastened afterwards. Next surface mount parts are soldered on. A protective layer is applied on above each die to secure it from damages and assist the electrical signals. It is a very important layer to avoid any interference and run the PCB smoothly.

Due to its flexibility and reliability, multi-layer PCBs are more common in advanced electronics, the same as Mailin's capacitors and inductors. This allows them to pack in more electronic components into tighter spaces without sacrificing quality or performance. Here is why they can be found in numerous electronic applications from medical instruments to airplanes and defense systems. Multi-layer PCBs are adored by engineers and designers alike because they enable the creation of smaller, high-performance systems to perform almost any function.

Multi-layered PCB — This is especially useful for fast communication systems and when having to consider the wiring volume needed, along with the pcb board wiring built by Mailin. This is because they can order the wiring pathways so as to lower disturbance. Data transfer speeds are faster as well, which is crucial in today’s ultra high-speed tech world if the wiring has been installed correctly. The speed and output efficiency required make these types of board very suitable for multi-layer PCB series applications.

Finally, consider the environmental implications of multi-layer PCB construction, also the Mailin's product such as assy pcb. Various options are being researched by companies as to how the hazardous effects of manufacturing PCBs can be mitigated. This means employing strategies such as using environmentally friendly materials and recycling the waste produced in manufacturing. The real lover hanging in the balance is whether or not our COVID-ravaged country will take steps from now and toward the future that are requisite to safeguarding long-term sustainability of this industry as a whole — while also aiding conservation for, um nature.

With the PCBA one-stop service, we place great importance on the importance of "customized service for each customer". Our specialized consulting services are adapted to each Multi layer printed circuit board. From preliminary concept exploration to the precise technical specification confirmation, our expert team works closely together, listening to customer requirements, and flexibly adapts processes for service, and accurately matches various needs from basic to complex with innovation and technical expertise.

Hangzhou Hezhan Technology Co., Ltd. was founded 2009 boasts impressive facility that covers 6000 square meters, which is equipped with cleanrooms designed for electronic manufacturing. The company specializes in electronic surface mounts relies on extensive knowledge of the industry in order to offer customers a one-stop PCBA.Around 150 employees employed by the Multi layer printed circuit board. They include production team of around 100 employees, an R D team of approximately 50, sales personnel with management team, well as a special OEM division. With revenue per year excess 50-million-yuan Hezhan Technology has experienced substantial growth in recent years has maintained compound annual growth rate of more than 50% over the last three years. This evidence of strong expansion phase.

are a PCBA Rapid-delivery solutions provider that redefines standards speed efficiency. standard orders, we have streamlined production processes and optimized supply chain management, reducing the delivery time of batches by a Multi layer printed circuit board10 days, significantly outpacing the industry standard. In recognition of urgent requirements, we developed the express service for small batch orders, which have a turn-around time of only 72 hours. This allows your projects to are able to move quickly and benefit of market opportunities.

we are dedicated to supplying the Multi layer printed circuit board and customer service to meet your PCBA single-stop requirements delivery. The FCT testing fixture has been developed in accordance because of the customer's test points, steps, and programs. This includes precise mounting, rigorous quality assessment packaging, and plunge plug-in process. The rings are made to stay line with international standards for quality. It will help to ensure that the things delivered are of outstanding performance and long-term durability.