This blog is a part of the series on detailed overview and comparison - Multilayer PCB Vs. Single-layer PCB Allows delve into the interesting world of Multilayers Printed Circuit Boards (PCBs).. These backbone elements are common in our gadgets which all hold advanced-looking patterns giving power to the piece of tech we use on a frequent basis.

Actually, whenever you open an electronic piece of equipment what will appear is a small green board with tiny metal ways all in line and connected to this - that pretty much covers it as far as PCBs are concerned. But what are the traits that differentiate a multilayer PCB from others. Multilayer PCB vs Single-layer counterpart This extended space gives more room to move wires around, allowing you to create complex circuits.

With technology moving forward at its relentless pace, it comes as no surprise that PCB manufacturing has seen significant improvements. For many years, we had single-layer PCBs that were relegated to a singular layer of metal pathways in the days gone by. Skip to the Present, we can now manufacture a multi-layer PCB print that accommodates as many as 60 layers!!

An important development in the industry is that a laser can now penetrate all of these layers perpetrated by creating more productive and intricate octoplied board. Lasers perforate the sample, allowing layers to interconnect correctly so that electrical signals can flow.

Many of the electronic devices we use in our daily life, such as smartphones or computers can be easily interconnected into high density and multilayer PCBs that become staple building blocks. So, what does make them different from single-layer decked coatings? Multilayer PCBs, for example, allow you to fit more complicated circuits on a board. Also, they are great in signal quality and that is because the circuits can be distributed between several layers to avoid any noise from other electrical signals. Aside from that, multilayer PCBs are stacked and provide for smaller size devices with higher function.

What is Multilayer PCB? - A Complete Guide to Anatomy of Multilayer.

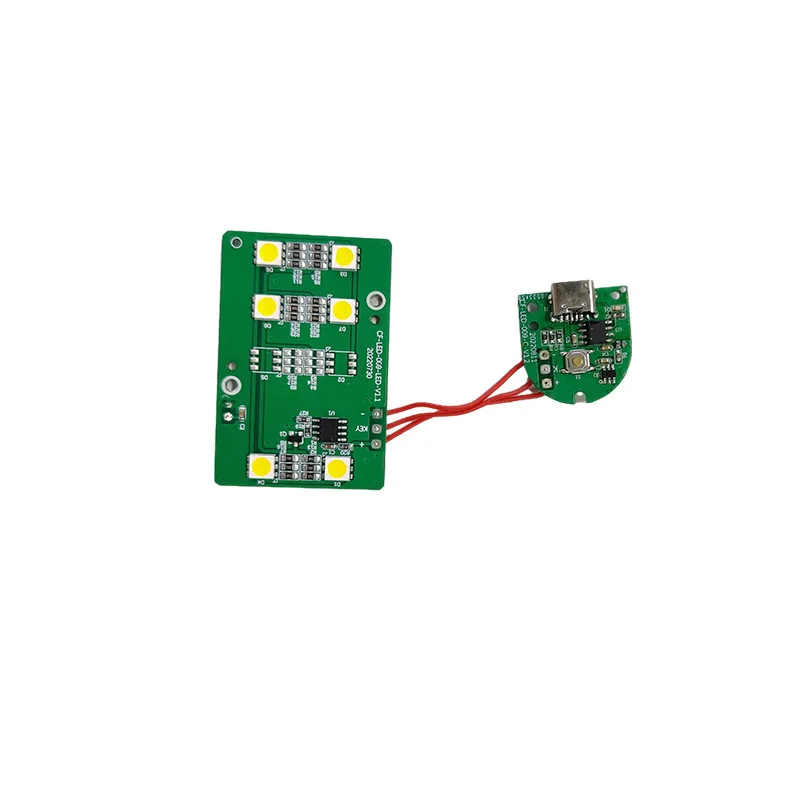

% Multilayer PCB layer sequence delivers the following structure consisting uniquely of top, bottom and more internal layers. Every single layer has its own distinct function which are interwoven together to create one cordial circuit. One key characteristic of DCL is that some layers are made using pre-preg, a fiberglass fabric with resin already applied. The resin melts and solidifies, welding the layers together around pre-preg interleaved within each when stacked. The layers are then interconnected via tiny holes called "vias. "

In the days when we approach a future where the need of technology is becoming smaller and more efficient, multilayer PCBs have become an indispensable. Multilayer PCBs help make designing and manufacturing smaller, more complex devices with numerous functions practical which enables technological advancement to move forward. As technology continues to advance, we can expect the development of increasingly more complex and intricate multilayer PCB designs that will allow for all sorts of novel applications within electronics.

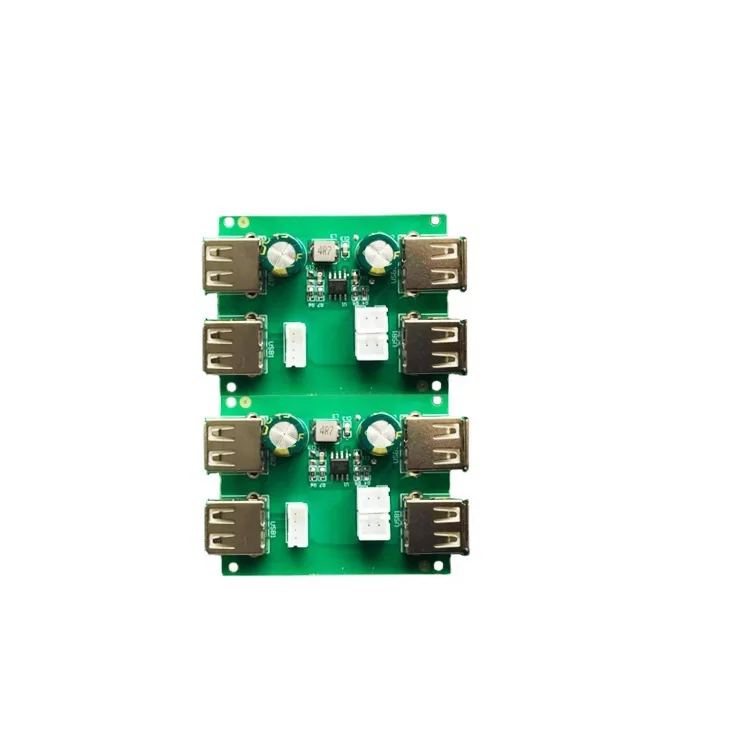

We'll offer you a multilayer printed circuit board service and a consignment to excellence in your whole PCBA requirements. From high-precision SMT technology that try mounting rigorous quality inspection packaging, to the ability of DIP plugin processing, and lastly PCBA testing as an integral step to be sure quality of delivery and production, FCT assessment fixtures are available and tested according to customer designed testing points, products and steps. The rings are created to be lined up and international standards for quality. This guarantees that the things delivered are of excellent performance along with longevity.

In 2009, company founded. Hangzhou Hezhan Technology Co., Ltd. boasts facility that covers 6,600 square meters, and equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company specializes electronic surface mounting rely extensive industry knowledge to provide clients with an all-in-one PCBA.The company has a total of 150 employees, which includes a production team about 100, a multilayer printed circuit board R D, sales, and management team that is roughly 50 people, as well as a special OEM division. With annual sales revenues in excess of 50 million yuan Hezhan Technology has experienced substantial growth in recent years, has maintained a compound annual growth rate at over 50% for the last three years. This is evidence of a strong expansion phase.

With the PCBA one-stop service, we place great importance on the importance of "customized services for each client". We offer exclusive one-on-1 professional consulting services that ensure every customer gets a customized solutions. From concept exploration through precise confirmation of technical specifications Our team of experts work closely with each other, attentively listening to multilayer printed circuit board requirements, and flexibly adjusts service processes and efficiently matches requirements for projects from simple to complex using innovation and technical strength.

specialize providing a one-stop PCBA quick delivery service that multilayer printed circuit board standards speed and efficiency. orders that are standard we have streamlined our processes production and improved supply chain management to reduce batch delivery times to a staggering 10 days, significantly outpacing industry standards. Moreover, recognition of urgent needs, we have pioneered express services for small batches with an impressive turnaround of only 72 hours, making sure the projects run smoothly and take advantage of market opportunities.