In prototype assembly, every thing is new creation. Its the stage where people borrow pieces from everywhere else and reassemble them to form what is called a prototype. Prototype is a trial version of the developable system as which it will be tested for its first appeal by its intended users. Its a design mock-up that helps the inventor understand how his idea will look and work.

Mainly when humans plan to create prototype they have make it work like what their aspects. This means they need to develop a doomed process so that they can see what the inevitable incoherent outcome of it will be before actually going ahead and doing anything. Planning was a key because makes us to avoid errors on latter stage. They also have to collect all the parts they require for that specific project. It may consist of wood, plastic or any number of other things. After that they take all the resources and start building prototype with those piece by piece.

A prototype is not a puzzle, putting pieces all together isn't the only thing it does; its creative! It's like an art form! Various combinations can be joined in many ways; some best fit different projects. Those who excel in prototype assembly are not weary of a multitude of techniques. They know how to select the one that is perfect for help they are doing and this can results in perfectly built prototype.

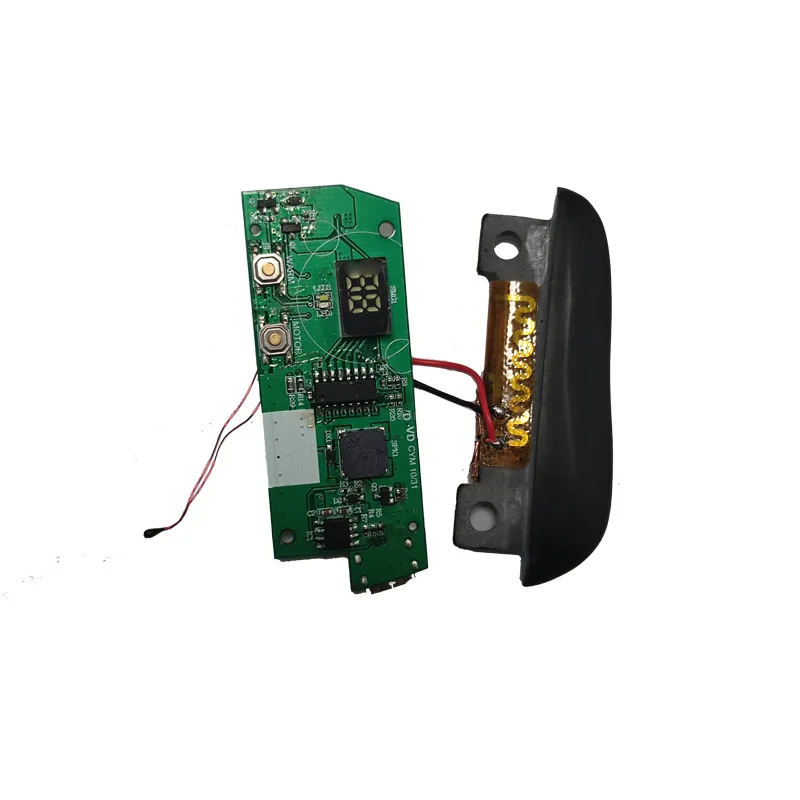

Soldering is one of a lot popular methods for assembling. WHAT YOU NEED TO KNOW Soldering is the melting of a metal rod (solder) and connecting to different items. Typically used for electronics. Gluing is also a common approach. This requires that you glue part of the model to another with a special type of adhesive for extra security. Tape Many people be thinking tape quick and dirty as well, Some who have used screws, nuts and bolts to assemble everything securely. All these methods have their own benefits depending on what the prototype requires.

We do a lot of prototyping and all want each prototype to be just right. This makes their work should be cautious and precise. Everything has to be prepared IN ADVANCE, so that it is perfect! We have to put everything in place, and make sure we do not commit any errors. A lot of times the parts are so small it's easy to miss one. Precision is a must to create an effective prototype.

The next step we tackle is the question about how to reproduce many copies of something after someone made a prototype. In Technical Terms This Is Called or Known as Production. Often making many prototypes can be difficult because they are often time-consuming to make each one individually. It is the reason why people search for a fatter and more efficient way to do it. To achieve for this you can do through the Machines. Save time- Certain computational problems can be done very fast by machines as well, and they do it accurately. Another approach is to have multiple people work together on the same project. In practice, this is called an assembly line, where individuals carry out discrete tasks which are then combined to produce the finished article.

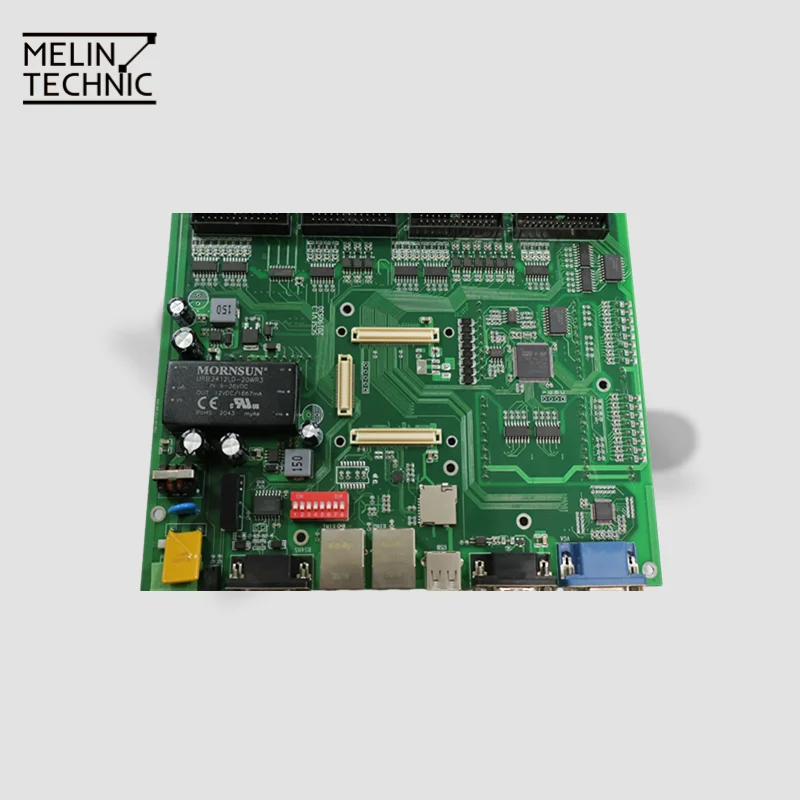

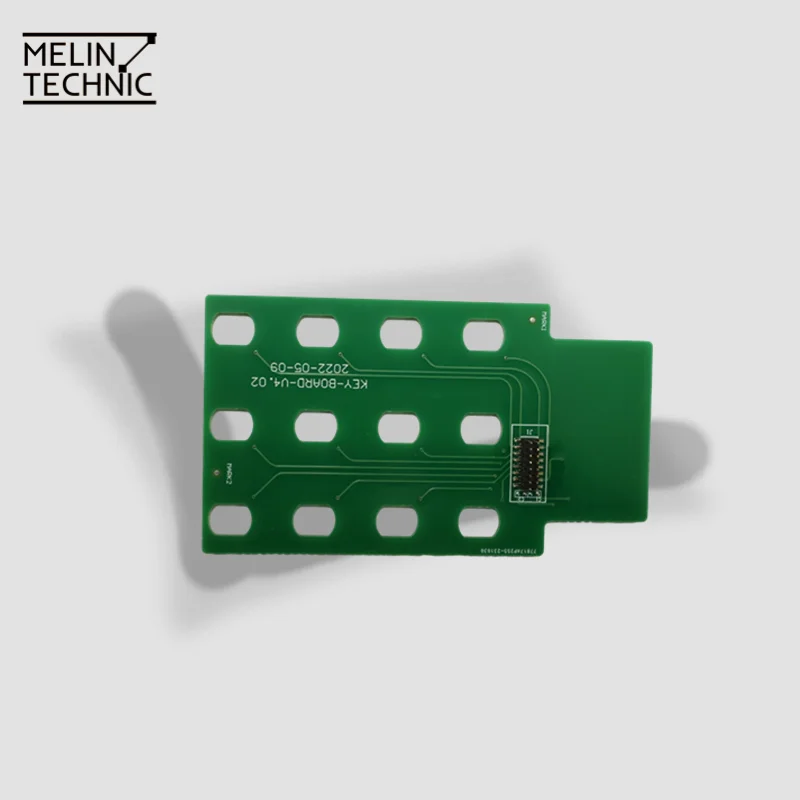

We are specialized in prototype assembly the highest standard and service for the PCBA one-stop delivery needs. With high-precision SMT mounting technology the strict quality of examination packaging, to the process capabilities of DIP plugin processing, and also to PCBA testing as an important step to ensure manufacturing and delivery quality. FCT testing tools are tested and manufactured in respect with customer created testing points programs and actions. Every ring was built to international guidelines of quality, making sure which these items delivered have actually outstanding performance as well as long-term durability.

We're aware of the specific requirements of every prototype assembly, so, when we offer the one-stop delivery service of PCBA, we attach great importance to the core value of "customized customer service". We offer exclusive one-on-one expert consulting services that ensure every client receives customized solutions. From concept exploration through specific confirmation of specifications for technical requirements our team of experts works closely together, listening to the needs of customers, flexible adjusts service processes and is able to accurately match various requirements for projects from simple to complex, utilizing innovation and technical expertise.

We are a PCBA supplier a rapid-delivery system that has set new standards speed effectiveness. We have optimized management of supply chain streamlined production processes to significantly reduce the time for delivery of batches to only 10 days. This is a prototype assembly improvement over industry norms. Because of the urgent demands, we pioneered the express service for small-scale orders, which has a turnaround time of just 72 hours. It allows your project to are ab le to move quickly and benefit of the opportunities on the market.

In 2009, company founded. Hangzhou Hezhan Technology Co., Ltd. boasts facility that covers 6,600 square meters, and equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company specializes electronic surface mounting rely extensive industry knowledge to provide clients with an all-in-one PCBA.The company has a total of 150 employees, which includes a production team about 100, a prototype assembly R D, sales, and management team that is roughly 50 people, as well as a special OEM division. With annual sales revenues in excess of 50 million yuan Hezhan Technology has experienced substantial growth in recent years, has maintained a compound annual growth rate at over 50% for the last three years. This is evidence of a strong expansion phase.