The mechanical improvements in the electronics have ended up as a standout amongst rapidly electric parts extremist states of improvement nowadays. That means one thing every year, smaller and more faster handset. The technology behind these devices are also improving day by drearier. What you may not know is the kind of SMD PCB board that plays an important role in this critical technology. In other words, SMD PCB boards are small circuit board containing so many components. So, to the running these boards in-stock and probably everything else matter we have some science.

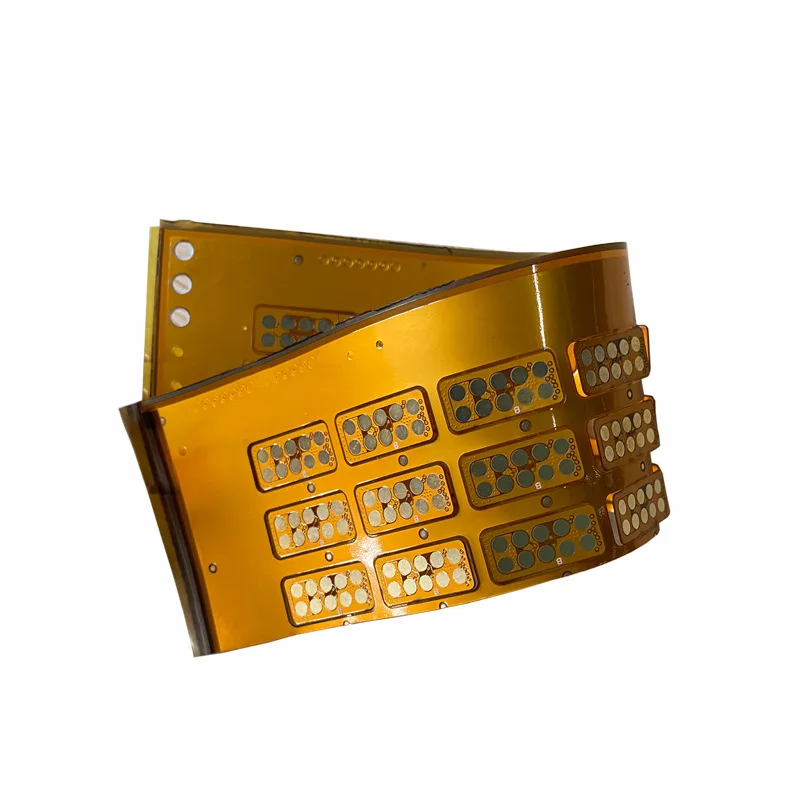

Surface-mount technology or SMT is a special manufacturing process that mounts parts directly onto the circuit board of your everyday electronics. These are obviously much more current than the antiquated electronic parts that must be mounted with wires which go through holes drilled in a board. SMD PCB boards are, however constructed to particularly smaller and part augmented which can be greatly profitable for space-saver.

SMD PCB boards are redefining electronics types and manufacturing with their introduction. They make the enviroments around devices smaller which makes them more unobtuse when we carry and use through things throughout day. However, most people already have small smartphones in their pockets and these boards are stronger than the older types -- which would often break with a jolt or even just from being bumped -- so they're theoretically more reliable for daily use.

SMD PCB: The Solutions For Electric Design Issues They are flexible for one. This smaller kind of package allows the close location of much tinier parts such as resistors and capacitors or transistors that do not have optimal physical space for connections. Which is great, because all of that flexibility also means engineers can make new electronic devices more complex and capable of doing even more stuff. Further, SMD PCBs are great to interface other major components like sensors, controllers etc. Therefore, they can be very well utilized for the fabrication of multifunctional electronic devices with high performance and low power consumption.

Advantages of using SMD PCB boards in manufacturing These are robust to be used for heat (it can sustains at a Temprature as higher than that what we get from recently cooked toast) and water. As such, they are ideal for automotive and power accessories applications or the demanding environments products where standard PCBs often fail. They are more cost-effective to produce than earlier board types (again, good for the small guys we work with). The components of SMD PCB boards are smaller too, reducing the device's weight and making it easier to carry or use by some individual. Those are all the more reason for our daily portable devices which we use.

So what kinds or factors we should think over to choose the right SMD PCB board for a projectWell first things is probably - which size of boards suits? It has to be as big as whatever device you want it for and having adequate area for all that goes on. Next, the configuration of board also matters to a great extent. That has to be the precise dimensions for this device so that everything would fit. Finally, choosing the right SMD PCB Board for your project -- either will it be just power control or else data-sharing options on this device.

We'll give you smd pcb board service and a determination to offer the very best for your PCBA requirements. Through the highest-quality SMT mounting technology a strict quality of packaging, to the capabilities of DIP plugin processing, and PCBA evaluation being a really important step to make sure high-quality production and delivery, FCT evaluation fixtures were created plus tested in accordance with customer created testing points, programs and processes. The rings is manufactured to satisfy international quality. This guarantees that this product delivered has outstanding performance long-term reliability.

Hangzhou Hezhan Technology Co., Ltd. was established 2009 and has an impressive manufacturing facility covering 6,600 square meters of space, equipped cleanrooms specifically madefacilitate electronic manufacturing. The company specializes electronic surface mounting and rely on extensive knowledge the industry in order to offer customers complete PCBA.company employs around 150 people by the company, which includes production team of around 100 people, a R D team of smd pcb board50, sales personnel with management team, as well as an OEM division that is special. Hezhan Technology, an annual revenue more than 50 million yuan seen significant growth in last couple of years. The compound annual growth rate the last three years is greater than 50%, which indicates that it is in a rapid expansion phase.

are a PCBA rapid-delivery service provider that redefines standards speed and efficiency. We have optimized supply chain management well as improved production processes dramatically reduce the delivery time of batch orders to only 10 days. This is a major smd pcb board over industry standards. Because of the urgent demands we introduced the express service for small batch orders with a turnaround time of just 72 hours. This allows your projects progress quickly, and you can take advantage of the opportunities on the market.

We're aware of the specific requirements of every smd pcb board, so, when we offer the one-stop delivery service of PCBA, we attach great importance to the core value of "customized customer service". We offer exclusive one-on-one expert consulting services that ensure every client receives customized solutions. From concept exploration through specific confirmation of specifications for technical requirements our team of experts works closely together, listening to the needs of customers, flexible adjusts service processes and is able to accurately match various requirements for projects from simple to complex, utilizing innovation and technical expertise.