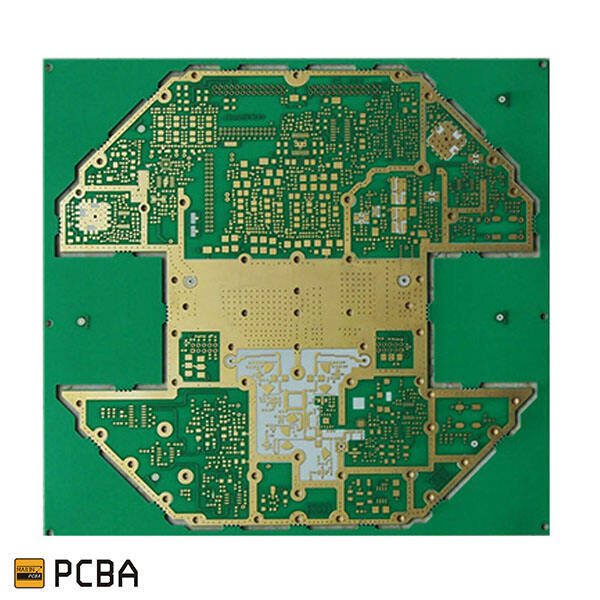

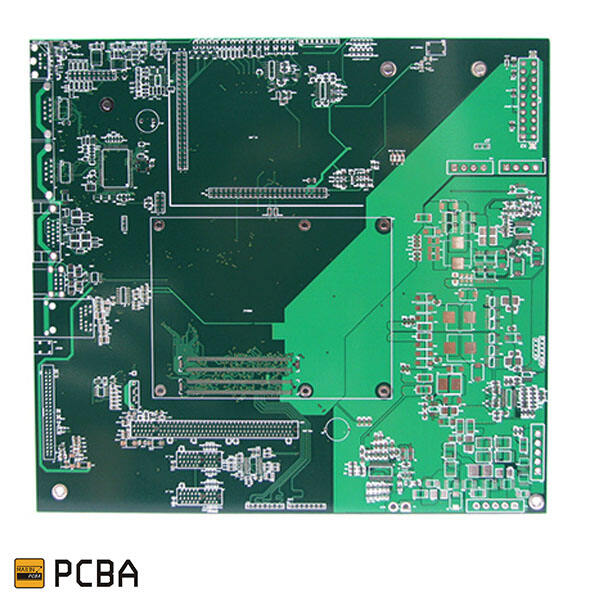

Circuit boards, specifically SMT circuit boards are vital in most of the applications that we all use on a daily basis. In essence, they are the intelligent brain of this machinery. SMT circuit board from mailin is a type of one category available circuit boards and the meaning of these terms we Call as Surface Mount technology. Such a process as above certainly secures electronic parts one by one on the printing circuit boards.

On SMT circuit boards there is a flat surface called traces which are used to hold small resistors, capacitors and integrated circuits. These traces - which not only deliver power, but they are also the way that components hook up and chat; meaning.. There are either adhesively or solder mounted onto the mailin board. Rather than conventional assembly methods, electronic printed circuit board technology benefits from its speed and preciseness. This is why it has become more popular in contemporary electronic production.

Modern Day Use of SMT Technology in Designing Circuit Boards Most notably, this allows for the creation of devices which are much smaller and lighter than current designs but do more with less power. Board sizes are also smaller because of the component minimization that SMT assembly does. Thus, this feature has the potential to allow for thinner and lighter devices such as smartphones or laptops. Lastly, the mailin SMT technology enables manufacturers to scale up their production and create more circuit boards in much less time with a lower rate of human error.

What Are The Most Common SMT Circuit Board Assembly Related Issues?

Nevertheless, there are some issues that can be met with SMT technology employed for the PCB assembly. The bridging is when solder makes an unintentional connection, between things that do not want to be connected. Very common. Fortunately, these are all correctable by changing where or how much you solder on your best circuit board.

Also in SMT circuit board design, then the production process will need to attach a number of components. The components, similarly to the board should have small footprint on a one hand and satisfy certain properties. Like resistors (control the flow of current) and capacitors( store/ run electric energy). If you select a far better quality components that are constructed to last, this will help the machine lasts for many years.

SMT technology is said to be the evergreen landscape, lying in position of top innovative ways in electronics industry. The new SMT assembly techniques have made the manufacturing part more precise and efficient. Manufacturers have done what they can to free up the space in order for these types of applications, using 3D printing capabilities that allow them to print custom parts directly onto an SMT board. You could even save time and increase accuracy by using a computerized pick and place machine to more rapidly and accurately set the components in their accurate locations on a board with an algorithmically controlled system.

To sum up, the metal core circuit board is a big part of technology nowadays. Additionally, they enable smaller and lighter devices to be produced while also reducing the production assembly times compared with traditional approaches. It does require assembly, which can be a hassle but as long you select the proper parts and troubleshoot it should run smooth. Ask SMT assembly moves on still, as will yield speeds and efficiencies.

In 2009, company founded. Hangzhou Hezhan Technology Co., Ltd. boasts facility that covers 6,600 square meters, and equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company specializes electronic surface mounting rely extensive industry knowledge to provide clients with an all-in-one PCBA.The company has a total of 150 employees, which includes a production team about 100, a Smt circuit board R D, sales, and management team that is roughly 50 people, as well as a special OEM division. With annual sales revenues in excess of 50 million yuan Hezhan Technology has experienced substantial growth in recent years, has maintained a compound annual growth rate at over 50% for the last three years. This is evidence of a strong expansion phase.

We are going to offer you a Smt circuit board service and a commitment to excellence in most your PCBA requirements. With high-precision SMT mounting technology strict quality packaging to your procedure capabilities of DIP plugin processing, and lastly PCBA testing as a crucial measure to guarantee manufacturing and delivery quality, FCT evaluation fixtures were created and tested to fulfill customer developed testing points, programs and steps. Every ring was created to worldwide quality, which ensures that these products delivered have powerful and long-term endurance.

In the PCBA one-stop service, we put a lot of emphasis on the value of "customized services for each client". We offer exclusive, one-on-one professional consultation services to ensure every Smt circuit board can receive tailored solutions. Our expert team can provide various solutions, from the initial exploratory phase to confirmation of specifications. They collaborate closely with the customer, adapt service processes flexibly and meet various requirements for projects, basic or intricate, with innovative thinking and technological power.

are a PCBA rapid-delivery service provider that redefines standards speed and efficiency. We have optimized supply chain management well as improved production processes dramatically reduce the delivery time of batch orders to only 10 days. This is a major Smt circuit board over industry standards. Because of the urgent demands we introduced the express service for small batch orders with a turnaround time of just 72 hours. This allows your projects progress quickly, and you can take advantage of the opportunities on the market.