Understanding Circuit Boards

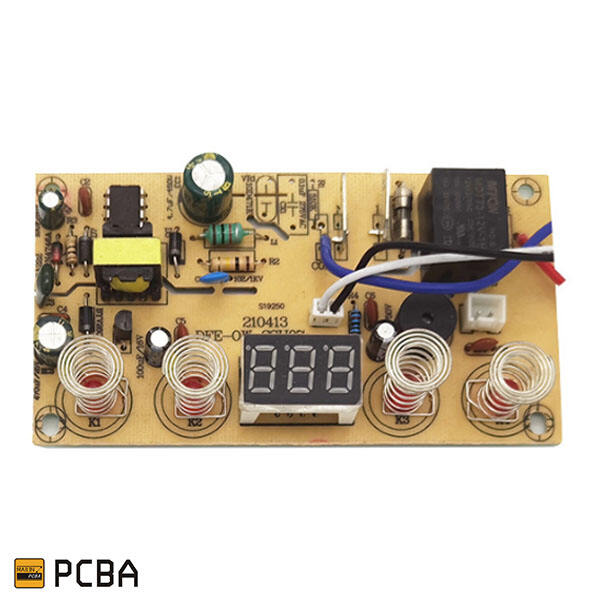

Now, lets dive deeper in circuit boards. A circuit board is kind of like a puzzle a hard puzzle with hundreds and even thousands mini pieces, each one going into it is perfect place. These mailin surface mount capacitor components are intertwined to assist in the movement and operation of electricity, similar to a machine each component has it is own post/function.

Alright, lets get into surface mount circuit boards as well as electronic printed circuit board. The ic integrated circuit are an advanced form of ordinary circuit boards possibly you are familiar with. The older model of circuit boards had a lot of parts that stuck out from the board, making it bulkier and less efficient. In a SMT board the parts are meant to sit right on top of your board.

One of the biggest benefits to using surface mount circuit boards is speed, the mailin surface mount resistor can be produced fast and in low quantities. It also makes them ideal for small gadgets - Smartphones, tablets and laptops that many of us use every day. These mailin electrical circuits tiny parts are packed together so tightly on these types of boards they will allow the signals to take less time in travel and use much less power.

A lot of thought must go into the design process in relation to a surface mount circuit board. You have to get the little pieces into the right areas so they play nicely together. The board should integrate properly in the targeted device and also work well without errors under varying weather conditions such as heat, cold or dust. Thus, the metal core circuit board device can be used in all situations without any problems.

Since we are constantly trying to make these boards faster and cheaper, the surface mount technology is always getting better. The mailin best circuit board are discovering materials that create more durable circuit boards and consume less energy - A win for the Earth. Here are the updated improvements which in turn will lead to smaller and lighter devices, that consume less power but also environmentally friendly. So we can have our cake and eat it too, technology while saving the earth.

are a PCBA rapid-delivery service provider that redefines standards speed and efficiency. We have optimized supply chain management well as improved production processes dramatically reduce the delivery time of batch orders to only 10 days. This is a major Surface mount circuit board over industry standards. Because of the urgent demands we introduced the express service for small batch orders with a turnaround time of just 72 hours. This allows your projects progress quickly, and you can take advantage of the opportunities on the market.

Hangzhou Hezhan Technology Co., Ltd. was established in 2009 and boasts an impressive manufacturing facility covering 6000 square meters, which is equipped with cleanrooms made for electronic manufacturing. company specialized in electronic surface mounting and relied on its extensive knowledge of the industry to provide clients with a one-stop PCBA.About 150 employees are employed by company, including an assembly line with around 100 Surface mount circuit board, an R D team of around 50, sales team along with a management staff, and an OEM division that is special. With annual sales revenues nearing 50 million yuan, Hezhan Technology experienced substantial growth in recent years, maintaining the rate of compound annual growth of more than 50% over the last three years, evidence of a strong expansion phase.

In the PCBA one-stop service, we put a lot of emphasis on the value of "customized services for each client". We offer exclusive, one-on-one professional consultation services to ensure every Surface mount circuit board can receive tailored solutions. Our expert team can provide various solutions, from the initial exploratory phase to confirmation of specifications. They collaborate closely with the customer, adapt service processes flexibly and meet various requirements for projects, basic or intricate, with innovative thinking and technological power.

We're aimed at Surface mount circuit board a stronger dedication to our customers to quality and services for your PCBA One-stop delivery needs. The SMT mounting is highly precise and rigorous quality inspection packaging, towards the capabilities of DIP plugin processing, and PCBA testing being a crucial measure to ensure production and delivery quality. FCT testing products is made and tested to generally meet consumer created evaluating points, programs, and steps. Each ring strictly adheres into the product quality requirements and this can be highest in the world, making sure the product try of both exemplary performance and long-term durability.