In our lesson for today, we are going to study on perforated circuit boards which play an integral role in several electronic device applications that have become a part of our daily lives. Soldering One of the a circuit board most important steps in manufacturing these boards is known as soldering. Soldering — connection of various elements to the board with a special metal called solder. For the plate to work properly this connection is crucial in nature. How to solder parts on your circuit board with holes. Here is a step-by-step guide that you will follow when you are adding different part onto the circuit board. First Step: You need to add little bit of tin around all the openings and afterwards heat them up so they flood.

Lastly, use a soldering iron (a hot metal melting tool) to melt the metal. The mailin solder will melt, and when it does so, which should happen in about 10-seconds or less of being on the metal for a base leg; providing heat onto that side as well is highly recommended — flow around the leg along with the bond to its respective bit.

Through hole Know-how is an previous strategy and used for very long time interval however it has its personal significance to in lots of digital merchandise even at the moment. Using this technology is advantageous for a number of reasons. There are different benefits and here we will be sharing some of the most significant ones:

A circuit board consists of a few different layers, each designed to serve its own purpose. These mailin layers include various materials including metal, fiberglass and plastic. The circuit board layers that are significant in the formation of circuit board;

Electronics were built very differently prior to the mailin pcb printed circuit board Surface mount technology than we find them today, where many components had long wire leads and either passed through holes in printed wiring boards or soldered though wires running over the circuits.

Interesting fact, Through-hole technology evolved over the years since its introduction in 1940s. Aside from these improvements, The pcba circuit board following are a number of significant changes and events throughout the course that has occurred over time;

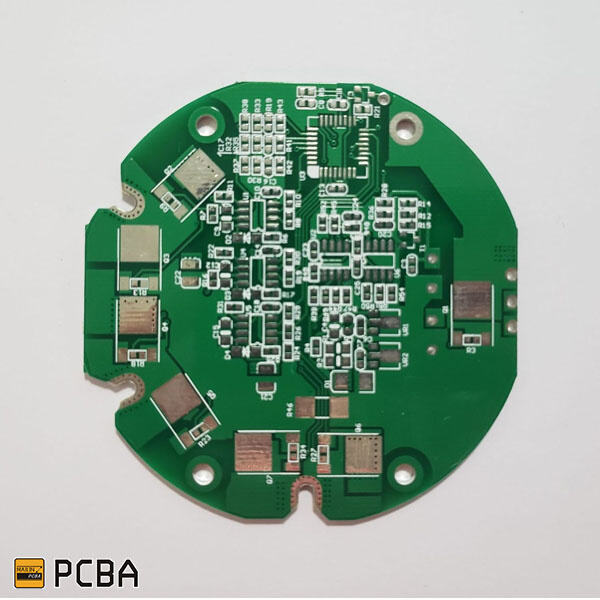

Now SMT and through hole technology are combined: now a days we have been using both smt components as well as the presence of through holes. The printed circuit board pcba combination of these qualities would allow us to make both high-strength and highly complex circuit boards required in the devices we use today.

In 2009, the company was founded. Hangzhou Hezhan Technology Co., Ltd. boasts facility that covers 6,000 square meters, equipped with modern cleanrooms specifically designed for electronics manufacturing. company specializes in electronic surface mounting and rely on its extensive knowledge of industry offer clients the complete PCBA.About 150 employees are employed by the company, which includes production team with about 100 people, an R D group about 50, sales staff as well as a management team. There also a special OEM division. Hezhan Technology, with an annual turnover close 50 million yuan, has witnessed significant growth over the past Through hole circuit board years. compound annual growth rate for the past three year is over 50%, which suggests that it is in a rapid expansion phase.

We're well-aware of the specific requirements of each client, therefore, in our one-stop delivery service for PCBA we give great importance to the core value of "customized customer service". Our specialized consultation services are designed to meet the needs of every client. From preliminary concept exploration to specific confirmation of specifications for technical requirements, our expert team works closely together, listening to the requirements of our Through hole circuit board, easily adapts processes for service and precisely matches specifications from simple to complex using innovation and technical power.

we are dedicated to supplying the Through hole circuit board and customer service to meet your PCBA single-stop requirements delivery. The FCT testing fixture has been developed in accordance because of the customer's test points, steps, and programs. This includes precise mounting, rigorous quality assessment packaging, and plunge plug-in process. The rings are made to stay line with international standards for quality. It will help to ensure that the things delivered are of outstanding performance and long-term durability.

are a PCBA rapid-delivery service provider that redefines standards speed and efficiency. We have optimized supply chain management well as improved production processes dramatically reduce the delivery time of batch orders to only 10 days. This is a major Through hole circuit board over industry standards. Because of the urgent demands we introduced the express service for small batch orders with a turnaround time of just 72 hours. This allows your projects progress quickly, and you can take advantage of the opportunities on the market.