Do you time yourself brushing your teeth or taking a shower? A timer circuit can help you with that and more! We can take a timer circuit as the thinking of small computer about time. It is used to synchronise different parts of a machine so that they work at the appropriate instant. This guide will show you how to make a timer circuit from scratch, including the construction and layout of one and even repair.

Now let us check out few of the basic parts to construct a timer circuit. Resistors, capacitors and other little electronic pieces are a part of these parts. These units could be regarded as the bricks of your circuit. You also need a computer program to tell you how your circuit operates and help draw it before actually building one. Since this software helps you organize things better and plan first. After collecting all your analog and digital parts, making finalize list of thier connections its time you start builfing timer circuit with physical components using board. This is where you will link everything together. Follow the directions carefully and exercise caution when using tools like soldering irons and other equipment. SAFETY FIRST ALWAYS

This first requires selecting good parts and carefully setting up the board so that your timer circuit turns out functional. At the same time, you must asses how it performs in various environments. With further development of technology the hardware can be tested on computer with known softwares which tells you just to check the software without making it physically. This is a very good way to prevent any issues in the future. A final important consideration: how much power does your timer require to operate correctly? You need to ensure that the bike can power itself up for smooth operation. That being said if we build with good quality parts, secure all connections and layout the circuit well our timer should perform as expected so shall see how it behaves when I use in future.

There are multiple ways to employ a timer circuit, and that makes it the fun of his. By adjusting to a schedule, it can be used, for instance with lights and appliances in your home. Picture your lights coming on when the sun goes down, or have an espresso maker preparing only before you rise. It can be also used in health devices such as blood pressure monitor to record data over time. Timer circuits are useful in operating together machines or sounding alerts when provided with an impact. This means they can contribute to ensuring all operations run seamlessly and safely. You can use a timer circuit to automate what is otherwise wasteful manual exercise and just do things you might fail with doing manually, such as not skipping chores.

At times your timer circuit might not work as intended. It may have joined elements that are off time or static, and could well be missing parts. If that is case, then you must very carefully try to understand what went wrong. A multimeter can be used for verifying the voltage as well as some other stuff in your circuit. This will give you the idea of what is going inside your circuit. Examine the wiring to see if it has come loose, other components on which parts may have broken or something else that needs fixing. If you are having further issues, it is better to consult the professionals online or follow tutorials which discuss how these can be fixed. Remember, there is nothing wrong with asking for help!

You should know little bit of programming to program your timer circuit. So it is necessary to know looping and its conditions as well. In other words, coding is the way of telling your timer circuit how to work. Great for beginners - you can use ready made code; But don't worry if that seems more like a headache to you, feel free to write your code from scratch also. Do not forget to have a backup of your code in with you, if anything goes wrong. You also want to testing your code so that it functions as you imagine. With testing you can discover any errors and put them right before preparing your final circuit.

We're a PCBA supplier a rapid-delivery system that set new standards speed and effectiveness. have improved our supply chain management as well as streamlining our production processes to reduce batch delivery time to only 10 days. This is a huge timer pcb circuit over industry norms. Additionally, wake of pressing demands, we've created express services for small batches, which have a remarkable turnaround time of just 72 hours, which will ensure that the projects run smoothly and take advantage of opportunities in the market.

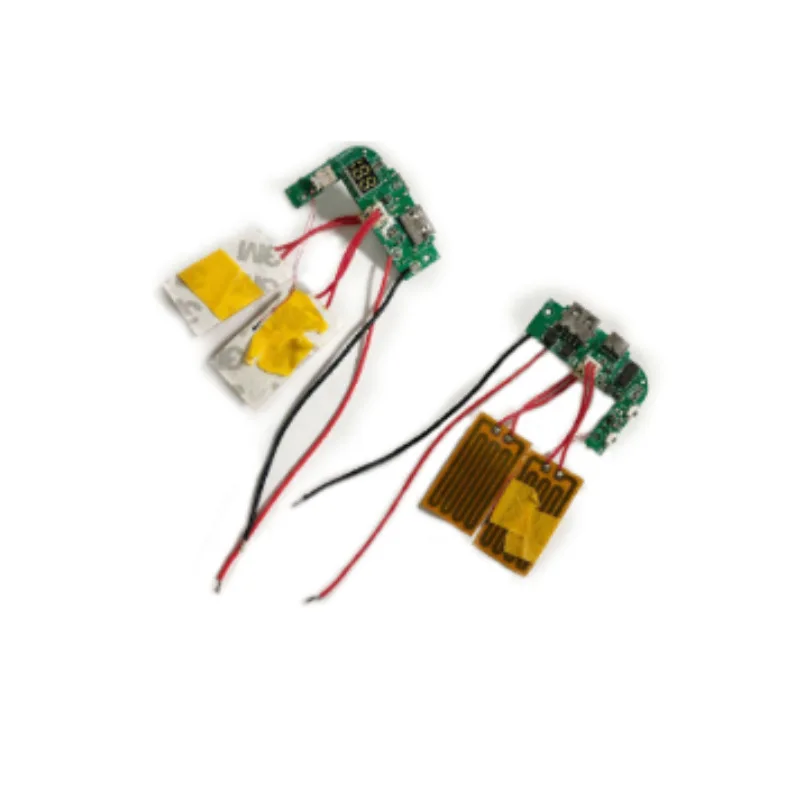

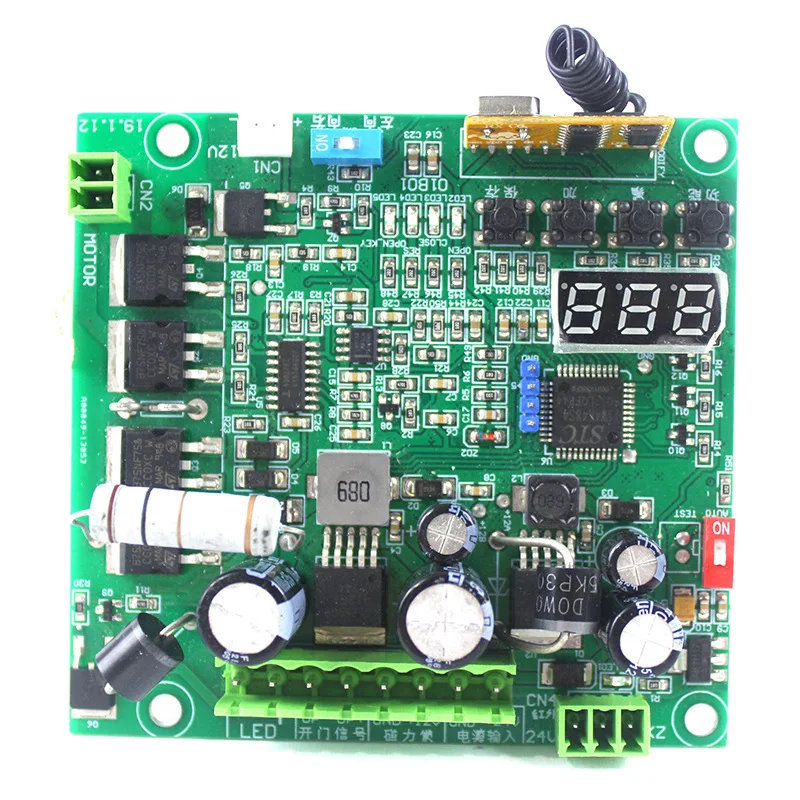

We're aimed at timer pcb circuit a stronger dedication to our customers to quality and services for your PCBA One-stop delivery needs. The SMT mounting is highly precise and rigorous quality inspection packaging, towards the capabilities of DIP plugin processing, and PCBA testing being a crucial measure to ensure production and delivery quality. FCT testing products is made and tested to generally meet consumer created evaluating points, programs, and steps. Each ring strictly adheres into the product quality requirements and this can be highest in the world, making sure the product try of both exemplary performance and long-term durability.

We are aware of the individual needs of each timer pcb circuit, why, in the one-stop delivery service of PCBA we give great importance to the principle of "customized customer service". We provide exclusive one-on-one professional consultation services to ensure each customer receives individualized solutions. From initial concept exploration to precise confirmation of technical specifications Our expert team works closely together, patiently listens to customer requirements, and flexibly adapts the service process and efficiently matches needs from basic to complicated with creativity and technical rigor.

Founded in 2009, Hangzhou Hezhan Technology Co., Ltd. boasts factory spanning 6000 square meters and is equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company leader research production electronic surface mounting, company based on its vast industry experience to provide customers with all-in-one PCBA solution, as well as expanding into small-batch production delivery options online.company currently employs around 150 employees, which includes production team approximately 100, a R D, sales, management timer pcb circuit of about 50 employees, as well as a specialized OEM division. Hezhan Technology, an annual turnover of close to 50 million yuan, has experienced significant growth last few years. company's annual compound increase over past three years more than 50%, suggesting that it is a rapid expansion phase.