Ever wondered how your electronic gadgets work? In this post I will take you in the world of PCB boards. PCB (Printed Circuit Board) is a small board, which controls the overall functioning of electronic devices. Historically, the gadgets were also reduced wires to bulky boards. But with the advancements in modern PCB technology, gadgets have shrunk yet become more powerful and efficient than ever.

Well, in this journey of ours today is introducing with a latest technology that name (Zero PCB Board). That the board can be used wirelessly, making it more convenient. The Zero PCB board uses electronic ink or paste to bond components rather than wires as seen in traditional boards.

Zero PCB Board Designs Grows Into Latest Developments

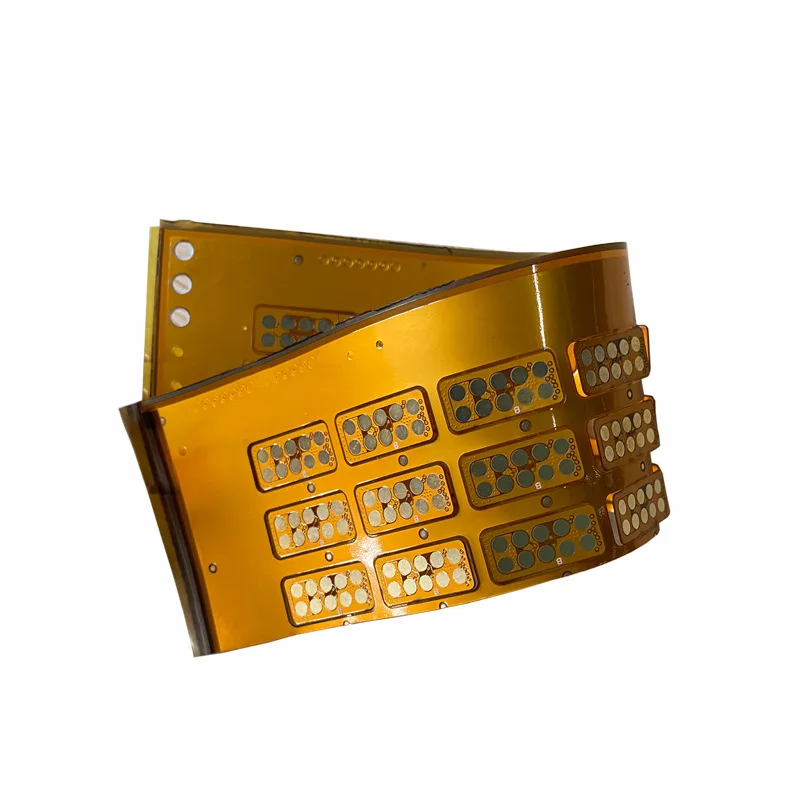

Today, Zero PCB board has reached its limit with the arrival of technology and designing which become more challenging when it comes to creativity. The most recent of these are the Flex and Rigid-Flex boards. By using use of mechanical vias this is called "Flex" technology and allows electronic devices to bend with the board retaining full functionality. Rigid-Flex & Flex The Flexible or flex boards can be bent once is being mounted(on loading) the same way a standard PCB will not withstand with this type of bendingne but, on otther hand in Rigid-flex board you are able to mount and bend it.

Zero PCB board technique has brought a transformation but the true impact of this revolution is on how we see electronic gadgets. Popular PCBsUsing these boards in a multitude of ways is possible which traditional illustrationa Printed signal forums are not capable offerings. They can be printed on different substrates (e.g., paper; plastics) allowing them to be contoured for an array of shapes and formed factors. It is especially useful for devices that need thin, light boards or have custom form factors.

Zero PCB boards are used in various household products which created many advantages. Besides being cheaper to produce because they use less material, these boards provide lesser number of and simpler design processes. In addition to that, their low power requirement is suited for battery-powered devices.

The innovation revolving the Zero PCB panels has been changing how things are done in the electronic gadget industry. These board types cost the very least to design and are highly advantageous in terms of sizingiena. So the market is ripe for a slew of new electronic devices.

Z ero PCB board technology is a light of advanced exploration in the electronic industry. Adopting Zero PCB boards enables innovating gadget design. Technological innovation will bring more development in Zero PCB board technology and this new era of electronic gadgets.

We're a PCBA rapid-delivery solution provider that redefines zero pcb board speed. orders that standard we have streamlined manufacturing processes improved supply chain management, reducing the duration of delivery for batches by a whopping 10 days, significantly outpacing industry standards. In recognition of urgent requirements, we pioneered the express service for small-scale orders, with a turnaround time of only 72 hours. ensures your projects are able to move quickly and benefit of opportunities in the market.

With the PCBA one-stop service, we place great importance on the importance of "customized services for each client". We offer exclusive one-on-1 professional consulting services that ensure every customer gets a customized solutions. From concept exploration through precise confirmation of technical specifications Our team of experts work closely with each other, attentively listening to zero pcb board requirements, and flexibly adjusts service processes and efficiently matches requirements for projects from simple to complex using innovation and technical strength.

Hangzhou Hezhan Technology Co., Ltd. zero pcb board in 2009 has an impressive factory covering 6,000 square meters, complete with cleanrooms that are specifically created to facilitate electronic manufacturing. company specialized in electronic surface mounting and relied on extensive industry knowledge order to offer customers an all-in-one PCBA.The company employs approximately 150 employees. This includes production staff of about 100, a R D, sales, management team roughly 50 employees, and a special OEM division. Hezhan Technology, with an annual revenue over 50 million yuan, witnessed significant growth in the last couple years. The company's average annual growth rate for the last three years more than 50%, suggesting that is in a rapid expansion phase.

We are specialized in zero pcb board the highest standard and service for the PCBA one-stop delivery needs. With high-precision SMT mounting technology the strict quality of examination packaging, to the process capabilities of DIP plugin processing, and also to PCBA testing as an important step to ensure manufacturing and delivery quality. FCT testing tools are tested and manufactured in respect with customer created testing points programs and actions. Every ring was built to international guidelines of quality, making sure which these items delivered have actually outstanding performance as well as long-term durability.